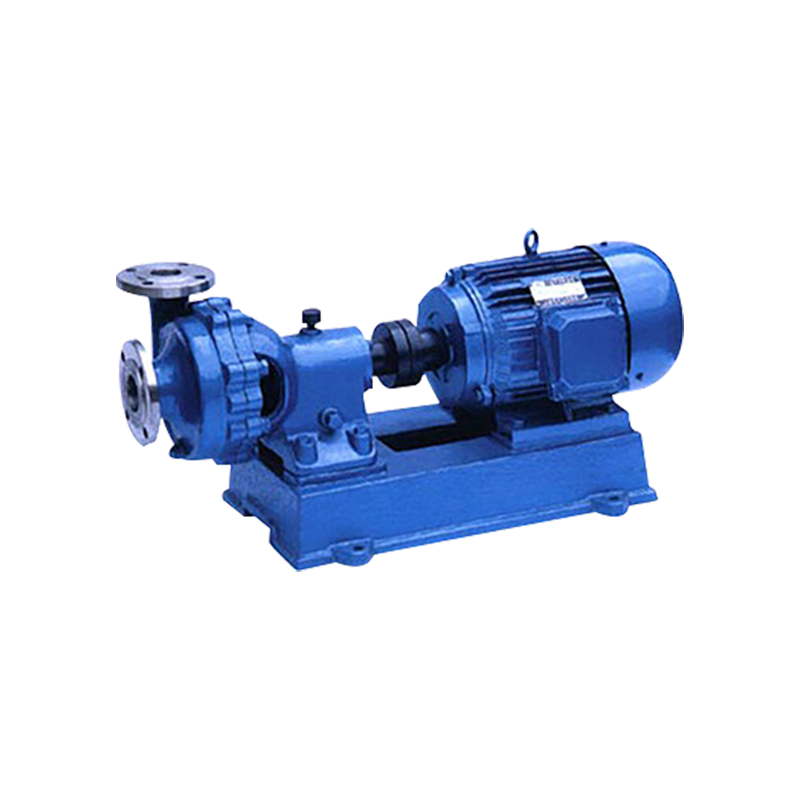

Chemical process pumps are essential components in industries where the precise handling of liquids and chemicals is critical. The...

READ MOREG-Type Screw Pumps Suppliers

Contact Us

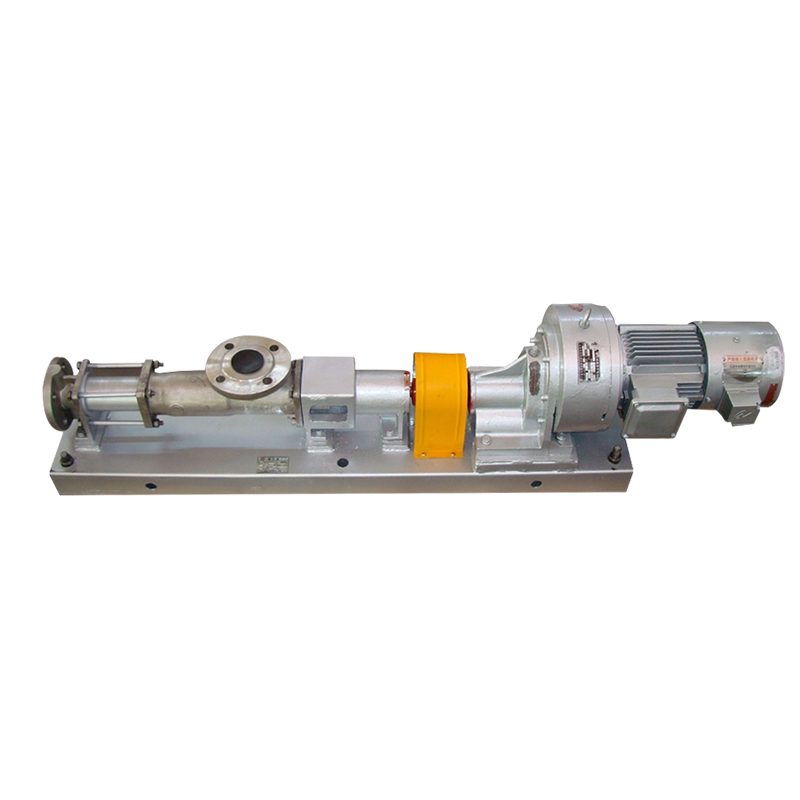

Working Principle of the G-Type Single Screw Pump

The G-type single-screw pumps primarily consists of a single screw and a stationary pump body. As the screw rotates within the pump body, it continuously transports the liquid along the helical grooves of the screw to the pump outlet. Specifically, when the screw rotates, the liquid is gradually pushed towards the pump outlet due to the screw's helical motion.

The working process can be broken down into the following steps:

Liquid Inlet

As the screw rotates, the helical grooves inside the pump body gradually expand, creating a negative pressure area that draws the liquid into the pump body.

Liquid Transport

The liquid moves along the axial direction within the helical grooves of the screw. Due to the continuous rotation of the screw, the liquid is pushed towards the pump outlet.

Liquid Discharge

The liquid is eventually squeezed out of the pump body through the screw’s movement, completing the transportation process.

Main Features of the G-Type Single Screw Pump

Stable Flow Rate

Due to the continuous rotation of the screw, the G-type single screw pump can provide a stable flow rate, suitable for applications requiring consistent delivery.

Wide Applicability

This pump can handle various types of fluids, including those with high viscosity and those containing solid particles.

Strong Self-Priming Ability

The G-type single screw pump has good self-priming capabilities, allowing it to operate normally even when the liquid is at a higher position in the pump body.

Low Pulsation

Its structural design allows the G-type single screw pump to provide low-pulsation flow output, reducing system vibration and impact.

Easy Maintenance

With its simple structure, the pump is easy to disassemble and maintain, which helps to extend the equipment’s service life.

Due to its desirable performance, the G-type single screw pump is widely used in various industries, including but not limited to:

-

gtype-single-screw-pump-application

-

Petrochemical Industry

Petrochemical Industry

Used for transporting various chemical raw materials, oils, and viscous substances.

-

Food Processing

Food Processing

Used for transporting food ingredients and fluids required in food processing, such as juices and sy...

-

Wastewater Treatment

Wastewater Treatment

Used for handling wastewater with solid particles, suitable for use in wastewater treatment plants.

-

Paper Industry

Paper Industry

Used for transporting paper pulp and other fluids required in paper processing.

-

Pharmaceutical Industry

Pharmaceutical Industry

Used for transporting pharmaceutical raw materials and liquids, meeting strict hygiene requirements.

Summary

The G-type single screw pump, with its unique working principle and performance, has become an indispensable piece of equipment in many industries. It not only provides efficient and stable fluid transportation but also boasts good self-priming capabilities and easy maintenance. Understanding the working principle and application areas of the G-type single screw pump helps in selecting the appropriate pump for practical use, enhancing production efficiency and equipment reliability.

| Model |

Speed(r/min) |

Flow rate(m3/h) |

Pressure(mpa) |

Motor power(kw) |

Head(m) |

Inlet(mm) |

Outlet(mm) |

|

G20-1 |

960 |

0.8 |

0.6 |

0.75 |

60 |

25 |

25 |

|

G20-2 |

960 |

0.8 |

1.2 |

1.5 |

120 |

25 |

25 |

|

G20-3 |

510 |

0.4 |

1.8 |

1.5 |

180 |

25 |

25 |

|

G20-4 |

510 |

0.4 |

2.4 |

2.2 |

240 |

25 |

25 |

|

G25-1 |

960 |

2 |

0.6 |

1.5 |

60 |

32 |

25 |

|

G25-2 |

960 |

2 |

1.2 |

2.2 |

120 |

32 |

25 |

|

G25-3 |

510 |

1.5 |

1.8 |

2.2 |

180 |

32 |

25 |

|

G25-4 |

510 |

1.5 |

2.4 |

3 |

240 |

32 |

25 |

|

G30-1 |

960 |

5 |

0.6 |

2.2 |

60 |

50 |

40 |

|

G30-2 |

960 |

5 |

1.2 |

3.0 |

120 |

50 |

40 |

|

G30-3 |

510 |

3 |

1.8 |

3 |

180 |

50 |

40 |

|

G30-4 |

510 |

3 |

2.4 |

4 |

240 |

50 |

40 |

|

G35-1 |

960 |

8 |

0.6 |

3.0 |

60 |

65 |

50 |

|

G35-2 |

960 |

8 |

1.2 |

4.0 |

120 |

65 |

50 |

|

G35-3 |

510 |

5 |

1.8 |

4 |

180 |

65 |

50 |

|

G35-4 |

510 |

5 |

2.4 |

5.5 |

240 |

65 |

50 |

|

G40-1 |

960 |

12 |

0.6 |

4.0 |

60 |

80 |

65 |

|

G40-2 |

960 |

12 |

1.2 |

5.5 |

120 |

80 |

65 |

|

G40-3 |

510 |

7 |

1.8 |

7.5 |

180 |

80 |

65 |

|

G40-4 |

510 |

7 |

2.4 |

11 |

240 |

80 |

65 |

|

G50-1 |

960 |

20 |

0.6 |

5.5 |

60 |

100 |

80 |

|

G50-2 |

960 |

20 |

1.2 |

7.5 |

120 |

100 |

80 |

|

G50-3 |

510 |

12 |

1.8 |

11 |

180 |

100 |

80 |

|

G50-4 |

510 |

12 |

2.4 |

15 |

240 |

100 |

80 |

|

G60-1 |

960 |

30 |

0.6 |

11 |

60 |

125 |

100 |

|

G60-2 |

960 |

30 |

1.2 |

15 |

120 |

125 |

100 |

|

G60-3 |

510 |

18 |

1.8 |

15 |

180 |

125 |

100 |

|

G60-4 |

510 |

18 |

2.4 |

18.5 |

240 |

125 |

100 |

|

G70-1 |

720 |

45 |

0.6 |

15 |

60 |

150 |

125 |

|

G70-2 |

720 |

45 |

1.2 |

15 |

120 |

150 |

125 |

|

G70-3 |

510 |

25 |

1.8 |

15 |

180 |

150 |

125 |

|

G70-4 |

510 |

25 |

2.4 |

18.5 |

240 |

150 |

125 |

|

G85-1 |

720 |

55 |

0.6 |

15 |

60 |

150 |

125 |

|

G85-2 |

510 |

55 |

1.2 |

18.5 |

120 |

150 |

125 |

|

G105-1 |

400 |

80 |

60 |

22 |

60 |

200 |

150 |

|

G105-2 |

400 |

80 |

120 |

30 |

120 |

200 |

150 |

|

G135-1 |

400 |

150 |

60 |

45 |

60 |

250 |

200 |

Common Technical Parameters of G-Type Single Screw Pumps

G-type single screw pumps are widely used in various industries due to their unique design and operational efficiency. Understanding their technical parameters is essential for selecting the right pump for specific applications. Below are some common technical parameters associated with G-type single screw pumps.

1. Flow Rate

The flow rate is a critical parameter that defines the volume of fluid the pump can move over a specified time. It is typically measured in liters per minute (L/min) or cubic meters per hour (m³/h). G-type pumps can handle varying flow rates depending on the application and pump size.

2. Viscosity Range

One of the significant advantages of G-type single screw pumps is their ability to handle fluids with high viscosity. The viscosity range is usually specified in centipoise (cP) and can vary from low-viscosity liquids to those exceeding several thousand cP, making them suitable for thick slurries, oils, and other viscous fluids.

3. Pressure Rating

The pressure rating indicates the pressure the pump can handle during operation. This parameter is typically expressed in bar or psi. G-type pumps are designed to operate under varying pressure conditions, making them versatile for different applications.

4. Temperature Range

The operational temperature range of G-type single screw pumps is essential, especially when dealing with heated or chilled fluids. This parameter is generally specified in degrees Celsius (°C) or Fahrenheit (°F) and can vary significantly depending on the materials used in the pump construction.

5. Material of Construction

The materials used in the pump's construction directly influence its durability and compatibility with various fluids. Common materials include stainless steel, cast iron, and various polymers. Each material offers different resistance to corrosion, wear, and temperature, making material selection crucial based on the application.

6. Suction Lift

Suction lift is the vertical distance from the fluid source to the pump inlet. This parameter is significant for applications where the pump is installed above the fluid level. G-type single screw pumps can typically achieve a suction lift of several meters, depending on the design.

7. Drive Options

G-type single screw pumps can be driven by various mechanisms, including electric motors, hydraulic systems, or pneumatic drives. The choice of drive affects the pump's efficiency, speed, and operational costs.

8. Seal Type

The type of sealing mechanism used in the pump affects its reliability and maintenance requirements. Common sealing options include mechanical seals, lip seals, and packing seals. The choice depends on the fluid being pumped and the operational environment.

9. Dimensional Specifications

The physical dimensions of the pump, including diameter and length, are important for installation purposes. It is crucial to ensure that the pump fits within the designated space in the facility.

Conclusion

G-type single screw pumps are versatile and efficient, with a wide range of technical parameters that make them suitable for various applications. Understanding these parameters helps in selecting the right pump to meet specific operational requirements. Whether handling viscous fluids, operating under high pressure, or dealing with varying temperatures, G-type pumps offer reliable solutions across many industries.

Jiangsu Feixiang Pump Manufacturing Co., Ltd. was founded in the 1980s. In 2001, Jiangsu Feixiang Pump Manufacturing Co., Ltd. was established by the Company Law. The company integrates scientific research, design, production, operation and service, and its corporate nature is a limited liability. It is now a member factory of the sound material resources network of Sinopec Group Corporation, a satisfactory network member factory of refining supplies and accessories of China National Petroleum Corporation, a key enterprise in the high-tech intensive zone of Jiangsu Province, an enterprise that abides by contracts and keeps promises, and the China General Mechanical Pump Industry Association. Member, self-operated import and export enterprise of the People's Republic of China.

The company has five workshops including casting, machining, fluoroplastic pump pressing, final assembly, and paint packaging, and five one-room functional departments including sales, technology, production, quality inspection, finance, and comprehensive office. G-Type Single Screw Pumps Suppliers in China, Custom G-Type Screw Pumps Factory. It currently has 256 employees, including 5 senior engineers, 28 engineers, 136 technicians, and 66 managers of various types. The company covers an area of 38,000 m2 and has fixed assets of 18 million yuan. The company has complete production equipment, physical and chemical testing, and testing equipment, and has a high-quality water pump performance testing center (measuring range flow: 0.5-20000m3/h, head: 2-2900m). The main products are produced using international standards and advanced foreign standards.

The company's reputable products include 26 series and 460 specifications and varieties. The main products are FXLB type non-clogging cyclone pump, ZA, CZ type chemical process pump, ZE type high-temperature pump, IJT type titanium nickel chemical pump, FIJ type alkali pump, IH type chemical centrifugal pump, FXP rotary jet pump, DF type multi-stage pump, WFB type sealless self-control self-priming pump, FSB type fluorine alloy pump, FIEC type dilute acid pump, FIU mortar pump, FYL type long Shaft submersible pump, SPP type chemical mixed flow pump, FJX type forced circulation pump, FCJ, FHJ desulfurization pump, JFRB double suction melt urea pump, JYM diaphragm metering pump, rotor pump, HZP type slurry pump, ZXB type self-priming Pump, OTS double suction pump, etc. G-Type Single Screw Pumps Wholesale.

The main materials of the product are 304, 304L, 316, 316L, CD4MCu, 904L, Mo3Ti, 20# alloy, TA2, TA3 pure titanium, TA9 titanium palladium alloy, Hastelloy, F46 fluoroplastic alloy, UHMWPE, steel lining, corrosion-resistant and wear-resistant rubber wait.

Feixiang products sell well all over the country and are widely used in petroleum, petrochemical, chemical, metallurgy, electric power, mining, medicine, light industry, food, automobile manufacturing, papermaking, environmental protection and other industries; among them, FXLB type non-clogging cyclone pump and FIEC type dilute acid pump, FIU mortar pump, JFRB double suction molten urea pump, IJT type titanium nickel chemical pump, FXP rotary jet pump and other products are widely used in petroleum, petrochemical, chemical, electric power, metallurgy, fertilizer and other industries to replace imported products, and are deeply loved by the majority of users. favor.

-

-

Chemical sewage pumps are specially designed pumps for transferring wastewater containing corrosive chemicals, suspended solids, a...

READ MORE -

Chemical process pumps are critical components in industrial plants, responsible for transporting corrosive, viscous, or high-temp...

READ MORE -

Fluorine lined axial flow pumps are specialized pumping solutions designed for handling large volumes of corrosive or chemically a...

READ MORE

en

en  русский

русский Español

Español