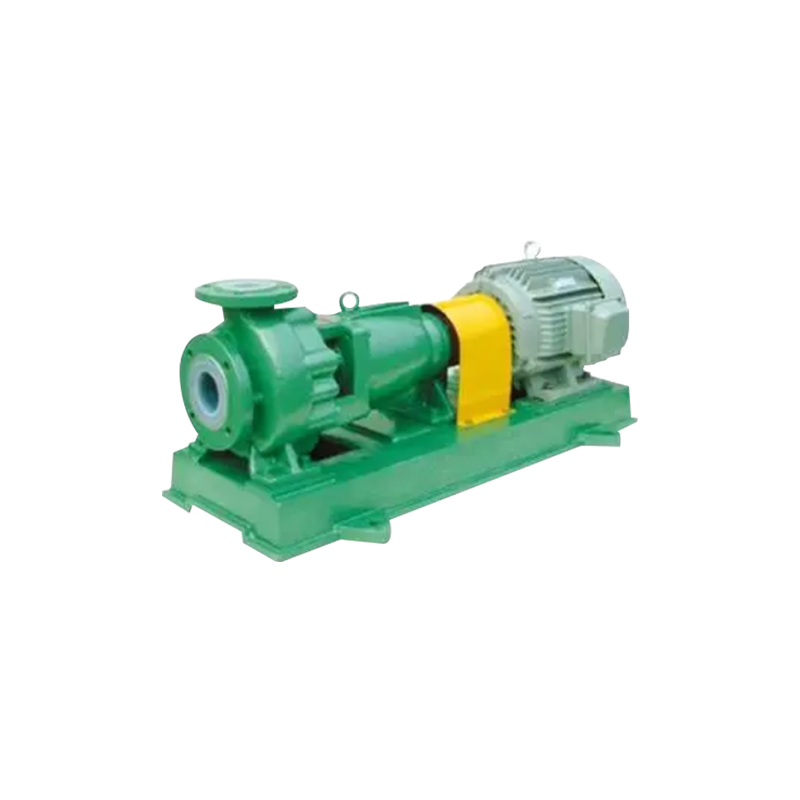

HJ Chemical Process Pump

Cat:Chemical Process Pump

1. Overview of the HJ chemical process pump HJ corrosion-resistant chemical process pump is a single-stage single-suction cantilever centrifugal pump....

See DetailsFluorine lined axial flow pumps are specialized pumping solutions designed for handling large volumes of corrosive or chemically aggressive fluids at relatively low heads. By combining the hydraulic efficiency of axial flow pump design with the exceptional chemical resistance of fluorine-based linings, these pumps deliver reliable performance in industries where standard metal pumps often fail prematurely. Typical applications include chemical processing, wastewater treatment, desalination, metallurgy, and power generation systems where corrosive media and continuous operation are common.

The fluorine lining is a critical component that directly affects pump performance. Materials such as PTFE, FEP, or PFA provide a smooth, non-reactive surface that minimizes friction, reduces chemical interaction, and protects the base metal structure. This lining allows the pump to maintain stable hydraulic characteristics even when handling highly corrosive fluids.

The low surface roughness of fluorine-lined interiors improves flow efficiency. Reduced friction losses translate into higher flow rates at the same power input, allowing axial flow pumps to operate closer to their design efficiency and deliver consistent output over long periods.

Fluorine linings are chemically inert to most acids, alkalis, and solvents. This stability ensures that the pump’s hydraulic geometry remains unchanged, preventing performance degradation caused by corrosion or chemical erosion.

Corrosion is one of the primary causes of pump failure in industrial systems. Fluorine lined axial flow pumps address this issue by forming a protective barrier between the pumped fluid and the metal components. This significantly extends service life and reduces the frequency of repairs or replacements.

Impellers, casings, and internal flow passages are continuously exposed to corrosive fluids. Fluorine linings prevent direct contact, preserving structural integrity and preventing thinning, pitting, or cracking that could compromise pump safety and efficiency.

Axial flow pumps are designed to move fluid parallel to the pump shaft, making them ideal for high-flow, low-head applications. When combined with fluorine lining, this design maximizes energy efficiency while maintaining chemical resistance.

The streamlined flow path reduces turbulence and energy loss. As a result, fluorine lined axial flow pumps can handle large volumes with lower power consumption compared to centrifugal alternatives in similar conditions.

Many industrial processes require pumps to operate continuously for extended periods. Fluorine lined axial flow pumps are well-suited for such conditions due to their resistance to wear and chemical attack, which helps maintain consistent performance without frequent shutdowns.

Maintenance costs are a major concern for pump operators. Fluorine lined axial flow pumps significantly reduce maintenance demands by preventing corrosion-related wear and minimizing fouling on internal surfaces.

The non-stick properties of fluorine materials reduce the buildup of scale and deposits. This makes inspection and cleaning easier and less frequent, saving both time and labor.

Although fluorine lined axial flow pumps may have a higher initial cost than standard pumps, their extended service life provides a strong return on investment. Fewer replacements, reduced spare parts consumption, and lower maintenance costs contribute to long-term savings.

| Factor | Standard Axial Flow Pump | Fluorine Lined Axial Flow Pump |

| Corrosion Resistance | Limited | Excellent |

| Maintenance Frequency | High | Low |

| Service Life | Shorter | Significantly Longer |

Fluorine lined axial flow pumps are adaptable to a wide range of industries due to their combination of performance and durability. They are commonly used in chemical transfer, acidic wastewater circulation, seawater handling, and cooling systems where corrosion resistance and high flow rates are essential.

Even under fluctuating temperatures, flow rates, or chemical concentrations, fluorine lined pumps maintain stable operation. This consistency reduces operational risks and improves overall system reliability.

By preventing corrosion-related leaks and failures, fluorine lined axial flow pumps contribute to safer plant operation and reduced environmental impact. Their long service life also means fewer resources are consumed for manufacturing replacements.

Fluorine lined axial flow pumps improve both performance and longevity by combining efficient hydraulic design with outstanding corrosion resistance. They deliver stable, high-flow performance, reduce maintenance requirements, and extend service life in demanding environments. For industries handling corrosive fluids and requiring continuous, reliable operation, fluorine lined axial flow pumps represent a practical and cost-effective long-term solution.