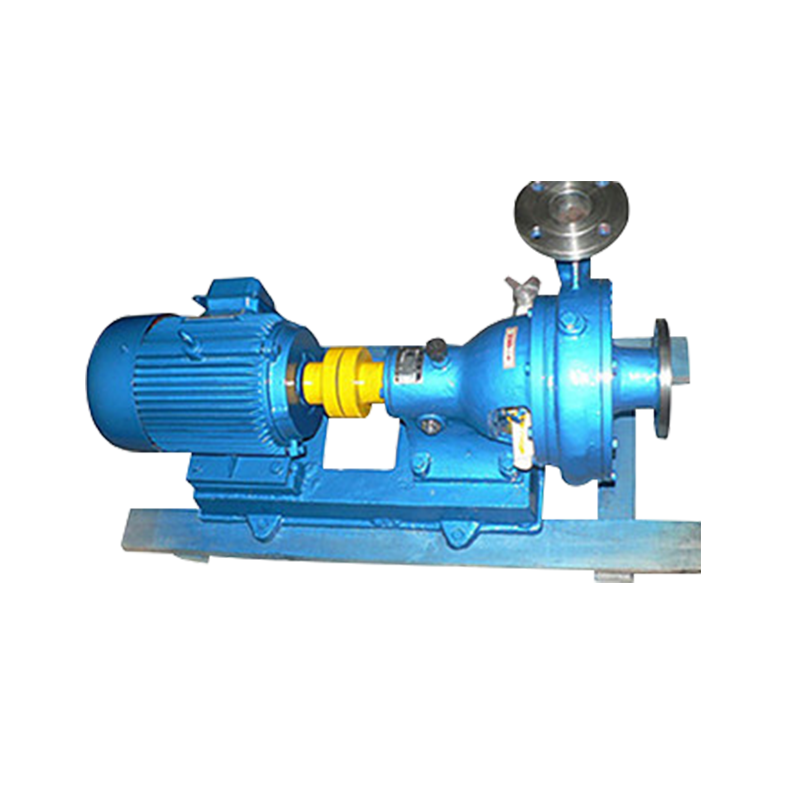

ZA Petrochemical Process Pump

Cat:Chemical Process Pump

1. OverviewZA and ZAO petrochemical process pumps are designed according to AP1610 and VDMA24297 (light/medium duty) specifications. 2. Application sc...

See DetailsChemical sewage pumps are specially designed pumps for transferring wastewater containing corrosive chemicals, suspended solids, and abrasive particles. Unlike ordinary sewage pumps, chemical sewage pumps use corrosion-resistant materials such as stainless steel, fluoroplastics, or coated alloys. These pumps are commonly used in chemical plants, pharmaceutical facilities, electroplating workshops, and wastewater treatment systems where the pumped liquid contains acids, alkalis, salts, or mixed industrial sewage.

Chemical sewage pumps are engineered for durability, safety, and stable performance in harsh environments. They must handle high chemical concentration, temperature variations, and solid particles without corrosion, erosion, or leakage. Key features include specialized impeller design, robust sealing systems, and reinforced pump casing. These pumps also offer reliable overload protection and low maintenance requirements, making them suitable for continuous operation.

The most critical feature is corrosion resistance. The pump’s wetted parts are made of materials that can withstand aggressive chemicals. Common materials include 316L stainless steel, Hastelloy, titanium, and PTFE-lined casings. For highly corrosive media such as hydrochloric acid or sulfuric acid, fluoroplastic coatings and non-metallic pumps are often preferred to prevent rapid wear and failure.

Industrial wastewater often contains suspended solids, sludge, and debris. Chemical sewage pumps use semi-open or vortex impellers to pass solid particles without clogging. Some models feature grinder or shredding mechanisms for fibrous materials. A correct impeller design improves efficiency and reduces blockage risks, ensuring stable operation.

Leakage is a major risk when pumping chemical sewage. Chemical sewage pumps often adopt mechanical seals with corrosion-resistant faces or magnetic drive seals to eliminate shaft seals. Seals may also include flushing and cooling systems to extend service life. For highly toxic media, magnetic drive pumps are favored because they can achieve true zero leakage.

Choosing the right chemical sewage pump requires understanding the characteristics of the liquid, required flow and head, and operating conditions. The selection should prioritize safety, corrosion resistance, and long-term reliability. A wrong choice can lead to frequent failures, high maintenance costs, and safety hazards.

First, identify the chemical composition, concentration, pH value, temperature, and viscosity of the sewage. Also consider whether the wastewater contains suspended solids, fibers, or abrasive particles. These factors determine material selection and impeller type. For example, high-viscosity sewage may require a pump with higher torque and a larger impeller.

Calculate the required flow rate (m³/h) and total head (m). Take into account pipe friction loss, lifting height, and system resistance. Selecting a pump with the correct duty point ensures stable operation and prevents cavitation or motor overload. In many cases, a pump with a slightly higher head is preferred to maintain performance under varying conditions.

Chemical sewage pumps come in several types, such as submersible pumps, centrifugal pumps, and magnetic drive pumps. Submersible pumps are suitable for pit or tank applications and provide quiet operation. Centrifugal pumps are widely used in chemical plants due to their high efficiency. Magnetic drive pumps are ideal for toxic or highly corrosive media because they eliminate shaft seals.

Chemical sewage pumps are used in a wide range of industries where wastewater contains chemicals, acids, alkalis, and suspended solids. Their applications include wastewater treatment, industrial drainage, chemical dosing, and process circulation. They are essential for maintaining environmental compliance and ensuring safe production processes.

Chemical plants generate wastewater containing acids, alkalis, solvents, and heavy metals. Chemical sewage pumps transfer this wastewater to treatment units, neutralization tanks, or filtration systems. They must withstand corrosion and prevent leakage to avoid environmental pollution and safety incidents.

Electroplating wastewater contains metal ions, acids, and alkaline cleaning solutions. Chemical sewage pumps used in this field must resist corrosion and handle suspended metal particles. Often, pumps with PTFE lining or corrosion-resistant alloys are selected to ensure long service life.

Pharmaceutical wastewater includes solvents, acids, and organic residues. Chemical sewage pumps in these industries must meet hygiene requirements while providing corrosion resistance. Many systems use sanitary pump designs and high-grade stainless steel to prevent contamination.

Proper maintenance is essential to ensure long-term performance and reduce downtime. Chemical sewage pumps operate in harsh environments, and improper maintenance can accelerate wear and cause leakage. A regular maintenance plan should include inspection of seals, impellers, and motor bearings, as well as checking for corrosion and vibration.

Inspect the pump casing, impeller, and inlet for blockage or buildup. Chemical residues can form deposits that reduce efficiency. Clean the pump periodically and flush the system with neutralizing solutions if necessary. Pay attention to the condition of the suction strainer and remove debris to prevent clogging.

Mechanical seals and bearings are critical components. Check for leakage, unusual noise, or vibration. If a mechanical seal shows signs of wear or leakage, replace it promptly. For magnetic drive pumps, ensure the magnetic coupling is intact and not overheated.

Monitor motor current, temperature, and vibration during operation. Abnormal values may indicate cavitation, blockage, or bearing failure. Keeping the pump operating near its best efficiency point (BEP) can reduce energy consumption and extend service life.

| Pump Type | Corrosion Resistance | Solid Handling | Leakage Risk | Typical Application |

| Centrifugal Pump | High (with correct materials) | Medium | Medium | Chemical plants, wastewater transfer |

| Submersible Pump | High | High | Medium | Pits, tanks, drainage |

| Magnetic Drive Pump | Very High | Low to Medium | Very Low (leak-free) | Toxic or highly corrosive media |

Chemical sewage pumps play a vital role in industrial wastewater management. Selecting the right pump requires understanding the chemical properties, solids content, flow requirements, and operating environment. By choosing corrosion-resistant materials, reliable sealing systems, and appropriate impeller designs, businesses can ensure safe and efficient wastewater transfer. Regular maintenance and monitoring further enhance pump reliability and extend service life, reducing costs and environmental risks.