Self-priming pumps represent one of the most practically valuable innovations in fluid handling engineering. Unlike standard centrifugal pumps that require the pump casing and suction line to be fully filled with liquid ...

READ MORESubmersible Pumps Manufacturers

Contact Us

-

Diversion Type Barrel Pump

The diversion type barrel pump series offers hydraulic performance, featuring a ...

-

Non-Metallic Vertical Submerged Pump

Overview The non-metallic vertical submerged pump is designed for handling corro...

-

Slurry Submerged Pump

The slurry submerged pump is a cantilevered vertical design developed by our com...

-

Molten Salt Submerged Pump

The molten salt submerged pump is a specialized high-temperature pump developed ...

Working Principle

The submerged pump functions by using an electric motor that is often hermetically sealed to prevent damage from contact with the liquid. The pump’s impeller is submerged in the fluid, and as it rotates, it generates suction that pulls the liquid through the intake. The fluid is then forced through the pump’s discharge nozzle.

These pumps are self-priming, which means they can start pumping without needing a separate priming process. The submersion ensures that the pump is always flooded with fluid, so the motor and impeller can work without interruption.

Key Features of Submerged Pumps

Submersion in Liquid: The most defining feature of a submerged pump is its ability to operate while fully submerged in the liquid. This design provides better efficiency and reduces the risk of cavitation compared to surface-mounted pumps.

Leak-Free Design: Many submerged pumps use a magnetic drive system or mechanical seals to prevent leakage, ensuring that hazardous or volatile fluids are safely contained.

Corrosion and Wear Resistance: Submerged pumps are often made from materials such as stainless steel, fluoroplastics, or ceramic composites, providing them with excellent resistance to corrosion and wear.

Self-Priming: Because the pump remains submerged, it does not need external priming mechanisms, simplifying its installation and operation.

Applications of Submerged Pumps

Submerged pumps are used across a variety of industries due to their versatility and reliability. Here are some common applications:

Chemical Processing: These pumps are ideal for handling corrosive chemicals such as acids, alkalis, and solvents. Their ability to safely transfer hazardous fluids makes them indispensable in chemical plants and laboratories.

Water and Wastewater Treatment: Submerged pumps are commonly used in wastewater treatment plants to transfer contaminated or untreated water and help with processes such as filtration and pH neutralization.

Oil and Gas Industry: Submerged pumps are used to move crude oil, sludge, and water from deep wells or storage tanks. They are also used in pumping stations for pipeline transportation.

Mining Industry: In mining, submerged pumps help transfer slurry—a mixture of water and solid materials—whether from the excavation or for dewatering applications in mines.

Marine and Aquaculture: These pumps are used to handle sea water and other fluids in aquaculture farms and shipboard systems, including ballast tanks and submarine pumping systems.

Types of Submerged Pumps

There are different variations of submerged pumps, each designed for specific applications:

Vertical Submerged Pumps: These pumps are designed with a vertical shaft, allowing them to pump liquids from deep sources. They are commonly used in water wells or deep storage tanks.

Centrifugal Submerged Pumps: These use centrifugal force to move liquids and are ideal for transferring high volumes of fluid quickly.

Peristaltic Submerged Pumps: These pumps use a mechanical squeezing motion to transfer liquids, making them suitable for transferring highly viscous or slurry-based fluids.

Magnetic Drive Submerged Pumps: These pumps utilize magnetic coupling to transfer energy to the impeller, eliminating the need for seals and preventing leakage.

Advantages of Submerged Pumps

Space Efficiency: Because the pump is completely submerged in the fluid, it requires less space on the surface, making it ideal for confined or limited areas.

Safety: Submerged pumps reduce the risk of leaks and exposure to hazardous fluids, which is crucial in industries dealing with dangerous chemicals or volatile substances.

Reduced Maintenance: With fewer moving parts exposed to external elements, submerged pumps generally require less maintenance compared to conventional pumps.

Noise Reduction: Submersion in fluid helps to dampen noise levels, making submerged pumps quieter than surface-mounted pumps.

Conclusion

Submerged pumps are indispensable tools in industries where fluid must be moved from deep or confined spaces. They offer energy efficiency, safety, and reliability, especially when handling corrosive, hazardous, or viscous liquids. Their self-priming ability, ease of installation, and minimal space requirements make them an attractive option for various industrial applications, including chemical processing, mining, and water treatment. Whether used in a high-temperature environment or for handling aggressive fluids, submerged pumps are a critical component in ensuring smooth and efficient operations in a range of sectors.

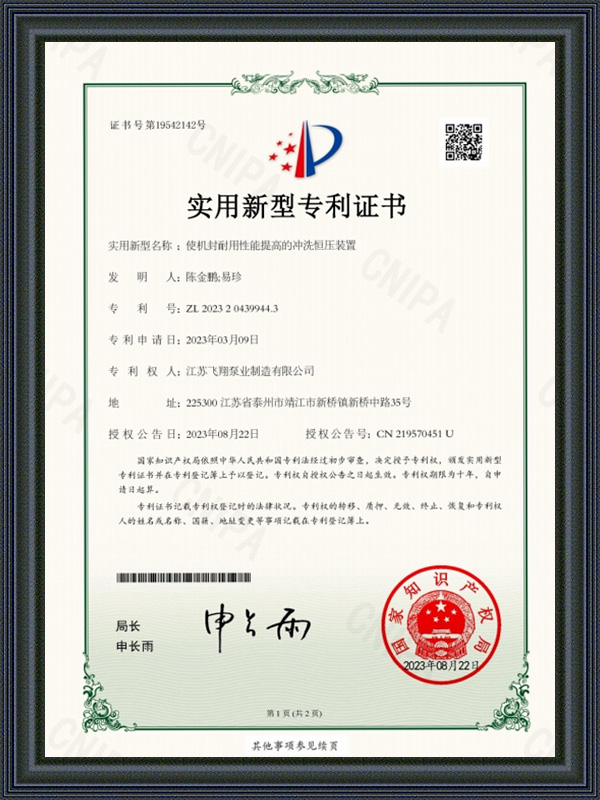

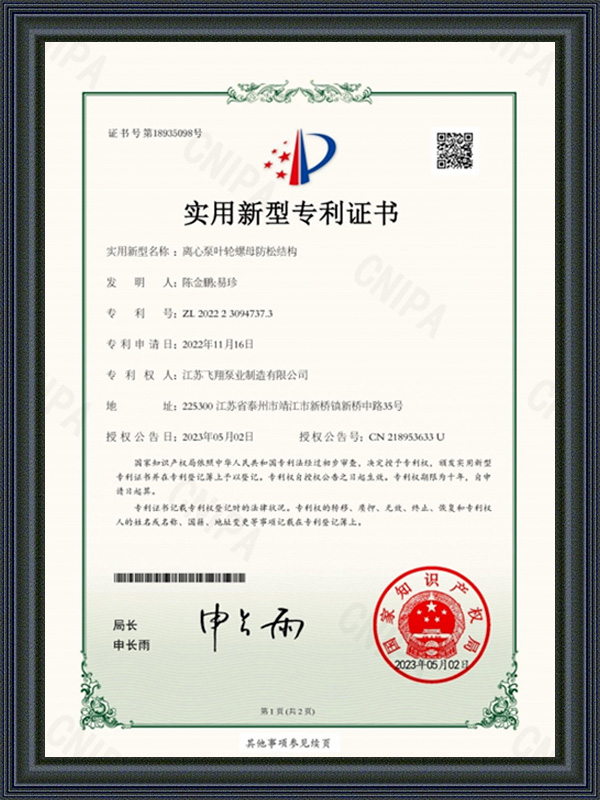

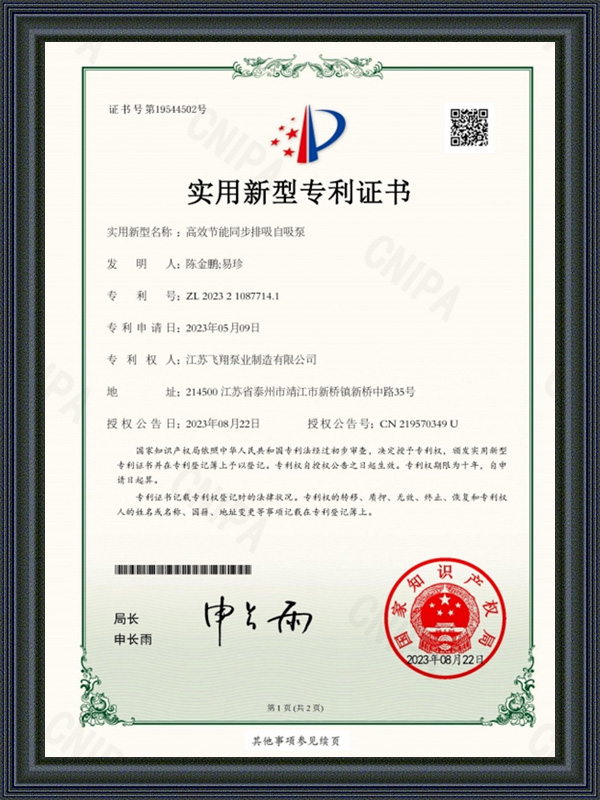

Jiangsu Feixiang Pump Manufacturing Co., Ltd. was founded in the 1980s. In 2001, Jiangsu Feixiang Pump Manufacturing Co., Ltd. was established by the Company Law. The company integrates scientific research, design, production, operation and service, and its corporate nature is a limited liability. It is now a member factory of the sound material resources network of Sinopec Group Corporation, a satisfactory network member factory of refining supplies and accessories of China National Petroleum Corporation, a key enterprise in the high-tech intensive zone of Jiangsu Province, an enterprise that abides by contracts and keeps promises, and the China General Mechanical Pump Industry Association. Member, self-operated import and export enterprise of the People's Republic of China.

The company has five workshops including casting, machining, fluoroplastic pump pressing, final assembly, and paint packaging, and five one-room functional departments including sales, technology, production, quality inspection, finance, and comprehensive office. Submersible Pumps Manufacturers and Submersible Pumps oem/odm Factory in China. It currently has 256 employees, including 5 senior engineers, 28 engineers, 136 technicians, and 66 managers of various types. The company covers an area of 38,000 m2 and has fixed assets of 18 million yuan. The company has complete production equipment, physical and chemical testing, and testing equipment, and has a high-quality water pump performance testing center (measuring range flow: 0.5-20000m3/h, head: 2-2900m). The main products are produced using international standards and advanced foreign standards.

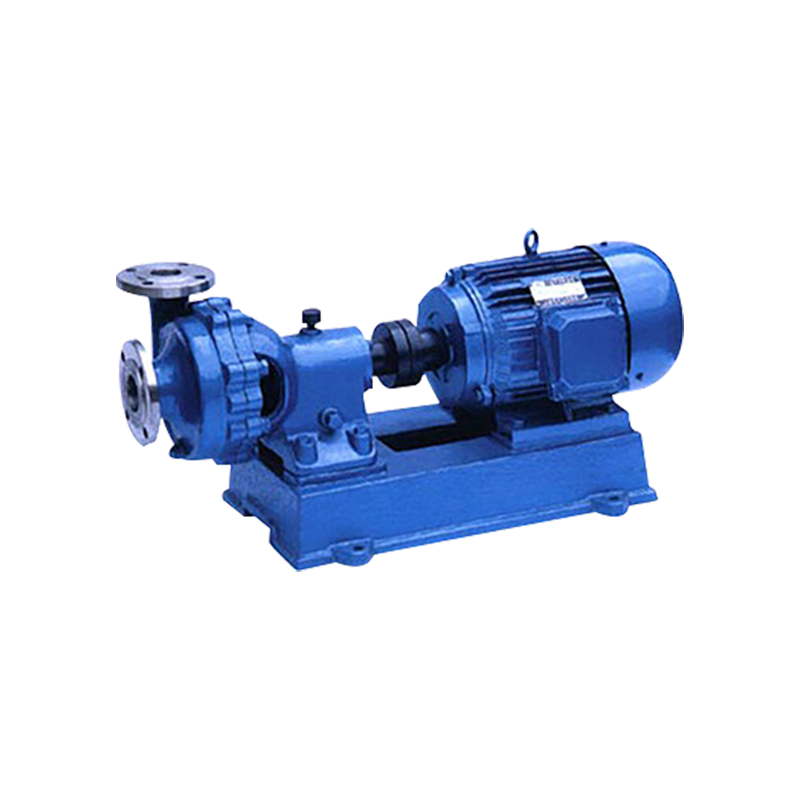

The company's reputable products include 26 series and 460 specifications and varieties. The main products are FXLB type non-clogging cyclone pump, ZA, CZ type chemical process pump, ZE type high-temperature pump, IJT type titanium nickel chemical pump, FIJ type alkali pump, IH type chemical centrifugal pump, FXP rotary jet pump, DF type multi-stage pump, WFB type sealless self-control self-priming pump, FSB type fluorine alloy pump, FIEC type dilute acid pump, FIU mortar pump, FYL type long Shaft submersible pump, SPP type chemical mixed flow pump, FJX type forced circulation pump, FCJ, FHJ desulfurization pump, JFRB double suction melt urea pump, JYM diaphragm metering pump, rotor pump, HZP type slurry pump, ZXB type self-priming Pump, OTS double suction pump, etc. Submersible Pumps Wholesale.

The main materials of the product are 304, 304L, 316, 316L, CD4MCu, 904L, Mo3Ti, 20# alloy, TA2, TA3 pure titanium, TA9 titanium palladium alloy, Hastelloy, F46 fluoroplastic alloy, UHMWPE, steel lining, corrosion-resistant and wear-resistant rubber wait.

Feixiang products sell well all over the country and are widely used in petroleum, petrochemical, chemical, metallurgy, electric power, mining, medicine, light industry, food, automobile manufacturing, papermaking, environmental protection and other industries; among them, FXLB type non-clogging cyclone pump and FIEC type dilute acid pump, FIU mortar pump, JFRB double suction molten urea pump, IJT type titanium nickel chemical pump, FXP rotary jet pump and other products are widely used in petroleum, petrochemical, chemical, electric power, metallurgy, fertilizer and other industries to replace imported products, and are deeply loved by the majority of users. favor.

-

-

Understanding Axial Flow Pump Design and Operation An axial flow pump is a dynamic pumping device that moves fluid parallel to the pump shaft axis, utilizing a propeller-like impeller to impart velocity and pressure to t...

READ MORE -

Understanding Chemical Process Pump Requirements Selecting the appropriate pump for chemical processing applications requires a comprehensive understanding of both the process requirements and the unique challenges posed...

READ MORE

en

en  русский

русский Español

Español