Self-priming pumps represent one of the most practically valuable innovations in fluid handling engineering. Unlike standard centrifugal pumps that require the pump casing and suction line to be fully filled with liquid ...

READ MORENetzsch Screw Pump Accessories Manufacturers

Contact Us

information to be updated

Common Replacement Parts for NETZSCH Screw Pumps

Routine maintenance and timely replacement of parts are vital for keeping NETZSCH screw pumps in ideal working condition. Here are some common replacement parts and their indications for replacement:

Rotor and Stator Assemblies

Description: These components are often replaced as a pair due to their interdependent function. Worn or damaged rotors and stators can reputable to decreased pump efficiency and performance.

Signs of Replacement: Decreased flow rate, increased vibration, or visible wear on the rotor and stator are signs that replacement may be needed.

Bearings

Description: Bearings support the rotor and ensure smooth rotation. Over time, bearings can wear out or become damaged.

Signs of Replacement: Unusual noises, increased vibration, or difficulty in rotation indicate that bearings may need to be replaced.

Seals

Description: Seals prevent leaks and protect the internal components of the pump. They may wear out or degrade over time.

Signs of Replacement: Fluid leaks, loss of pressure, or contamination of the pump's fluid are common signs that seals need to be replaced.

Shaft

Description: The shaft connects the rotor to the motor and transmits rotational motion. Damage or misalignment of the shaft can impact pump performance.

Signs of Replacement: Vibration, noise, or difficulty in operation may indicate that the shaft needs attention or replacement.

End Plates

Description: End plates seal the ends of the pump casing and support the rotor bearings. They can become damaged or misaligned.

Conclusion

Understanding the components and common replacement parts of NETZSCH screw pumps is essential for maintaining their performance and extending their lifespan. Regular inspection and timely replacement of worn or damaged parts help ensure the pump operates efficiently and reliably. By paying attention to these key components and recognizing the signs of wear, operators can effectively manage their NETZSCH screw pumps and minimize downtime.

Key Components of NETZSCH Screw Pumps

Rotor

Function: The rotor is a rotating screw that moves fluid through the pump. It is designed to create a continuous flow by forming sealed chambers with the stator. The rotor's helical shape and rotation facilitate the displacement of fluid from the pump’s inlet to its outlet.

Importance: The rotor's performance directly impacts the pump’s efficiency, flow rate, and the ability to handle various fluid types.

Stator

Function: The stator is a stationary component that surrounds the rotor. It is typically made of elastomeric or metallic materials and works in conjunction with the rotor to maintain the sealed cavities through which the fluid is pumped.

Importance: The stator’s design and material affect the pump’s performance, including its capacity to handle different fluids and maintain efficiency.

Bearings

Function: Bearings support the rotor shaft and allow it to rotate smoothly. They are essential for reducing friction and wear, ensuring stable operation of the pump.

Importance: Properly functioning bearings help maintain alignment and minimize vibration, contributing to the overall reliability of the pump.

Shaft

Function: The shaft connects the rotor to the driving mechanism (e.g., motor) and transmits rotational motion. It is crucial for the effective operation of the pump.

Importance: A well-maintained shaft ensures proper transmission of rotational force, which is essential for consistent pump performance.

Seals

Function: Seals prevent fluid from leaking out of the pump and protect internal components from external contaminants. They play a critical role in maintaining pump efficiency and safety.

Importance: Effective seals help avoid fluid loss and contamination, which can reputable to reduced performance or damage to the pump.

End Plates

Function: End plates are located at the ends of the pump casing and provide support for the rotor bearings. They also help in sealing the pump and maintaining internal alignment.

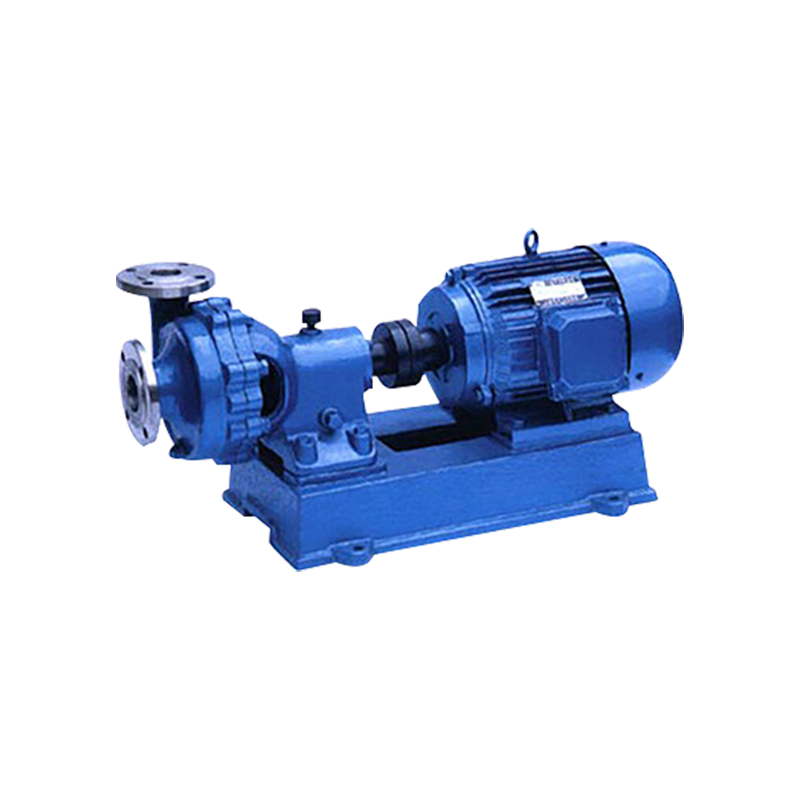

Jiangsu Feixiang Pump Manufacturing Co., Ltd. was founded in the 1980s. In 2001, Jiangsu Feixiang Pump Manufacturing Co., Ltd. was established by the Company Law. The company integrates scientific research, design, production, operation and service, and its corporate nature is a limited liability. It is now a member factory of the sound material resources network of Sinopec Group Corporation, a satisfactory network member factory of refining supplies and accessories of China National Petroleum Corporation, a key enterprise in the high-tech intensive zone of Jiangsu Province, an enterprise that abides by contracts and keeps promises, and the China General Mechanical Pump Industry Association. Member, self-operated import and export enterprise of the People's Republic of China.

The company has five workshops including casting, machining, fluoroplastic pump pressing, final assembly, and paint packaging, and five one-room functional departments including sales, technology, production, quality inspection, finance, and comprehensive office. Netzsch Screw Pump Accessories Manufacturers and Netzsch Pump Replacement Parts Factory in China. It currently has 256 employees, including 5 senior engineers, 28 engineers, 136 technicians, and 66 managers of various types. The company covers an area of 38,000 m2 and has fixed assets of 18 million yuan. The company has complete production equipment, physical and chemical testing, and testing equipment, and has a high-quality water pump performance testing center (measuring range flow: 0.5-20000m3/h, head: 2-2900m). The main products are produced using international standards and advanced foreign standards.

The company's reputable products include 26 series and 460 specifications and varieties. The main products are FXLB type non-clogging cyclone pump, ZA, CZ type chemical process pump, ZE type high-temperature pump, IJT type titanium nickel chemical pump, FIJ type alkali pump, IH type chemical centrifugal pump, FXP rotary jet pump, DF type multi-stage pump, WFB type sealless self-control self-priming pump, FSB type fluorine alloy pump, FIEC type dilute acid pump, FIU mortar pump, FYL type long Shaft submersible pump, SPP type chemical mixed flow pump, FJX type forced circulation pump, FCJ, FHJ desulfurization pump, JFRB double suction melt urea pump, JYM diaphragm metering pump, rotor pump, HZP type slurry pump, ZXB type self-priming Pump, OTS double suction pump, etc. Netzsch Screw Pump Accessories Wholesale .

The main materials of the product are 304, 304L, 316, 316L, CD4MCu, 904L, Mo3Ti, 20# alloy, TA2, TA3 pure titanium, TA9 titanium palladium alloy, Hastelloy, F46 fluoroplastic alloy, UHMWPE, steel lining, corrosion-resistant and wear-resistant rubber wait.

Feixiang products sell well all over the country and are widely used in petroleum, petrochemical, chemical, metallurgy, electric power, mining, medicine, light industry, food, automobile manufacturing, papermaking, environmental protection and other industries; among them, FXLB type non-clogging cyclone pump and FIEC type dilute acid pump, FIU mortar pump, JFRB double suction molten urea pump, IJT type titanium nickel chemical pump, FXP rotary jet pump and other products are widely used in petroleum, petrochemical, chemical, electric power, metallurgy, fertilizer and other industries to replace imported products, and are deeply loved by the majority of users. favor.

-

-

Understanding Axial Flow Pump Design and Operation An axial flow pump is a dynamic pumping device that moves fluid parallel to the pump shaft axis, utilizing a propeller-like impeller to impart velocity and pressure to t...

READ MORE -

Understanding Chemical Process Pump Requirements Selecting the appropriate pump for chemical processing applications requires a comprehensive understanding of both the process requirements and the unique challenges posed...

READ MORE

en

en  русский

русский Español

Español