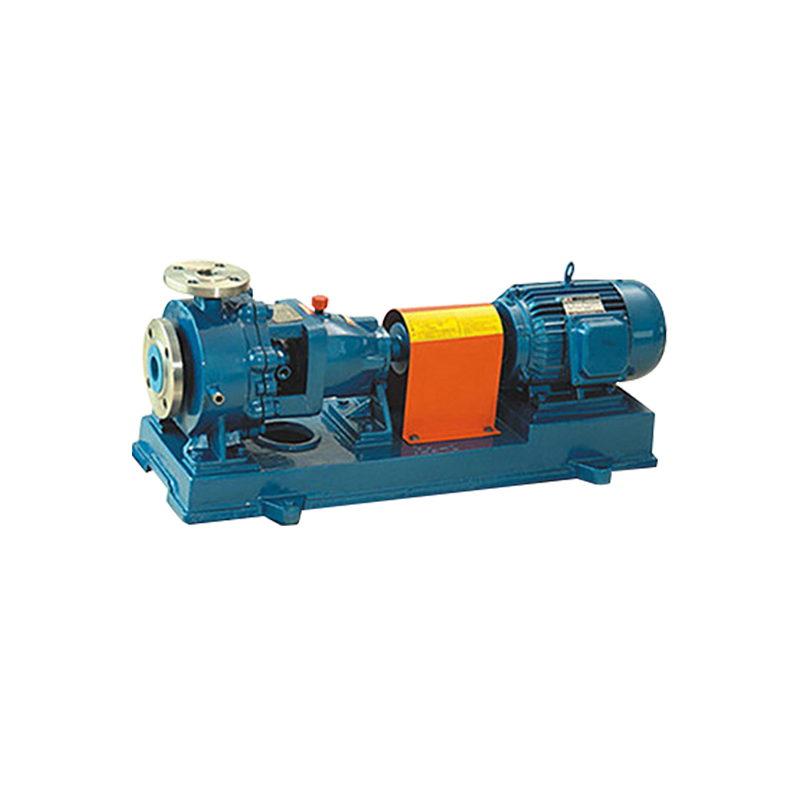

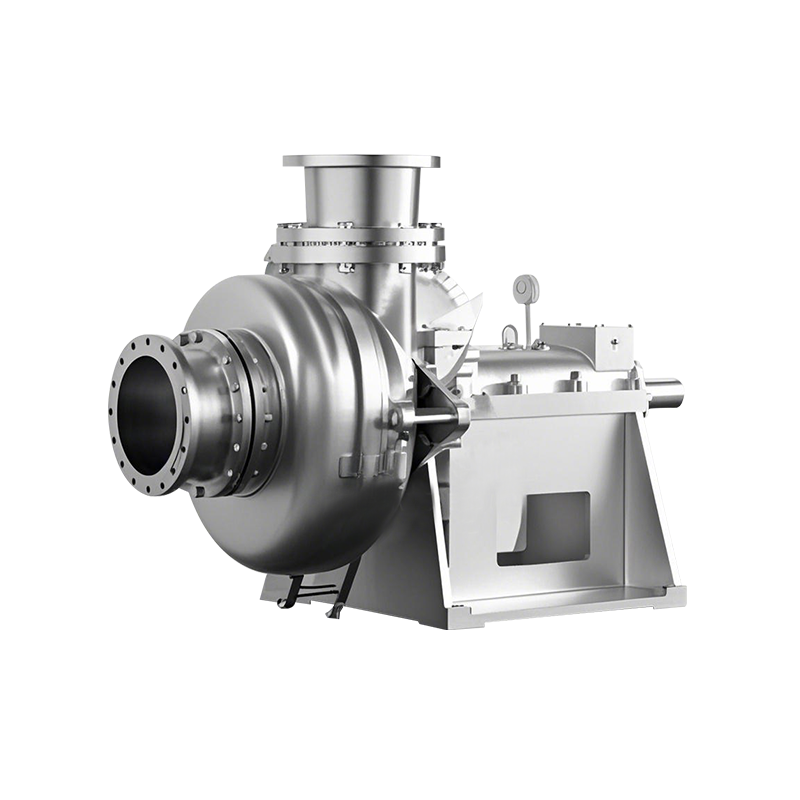

In modern chemical production, the transportation of liquids is an indispensable and important link. From highly corrosive acid and alkali solutions to high temperature, high pressure or high viscosity chemical media, the safe and stable transportation of liquids is directly related to the efficiency and safety of the entire production system. Chemical Process Pumps are key equipment that is widely used in this demand context, and they play an irreplaceable role in transporting chemical fluids and ensuring process continuity.

Core advantages

Excellent corrosion resistance

Chemical process pumps are made of special materials, which can effectively resist the corrosion of strong acids, strong alkalis, organic solvents and other media, and extend their service life.

Standardized structure and easy maintenance

Most chemical pumps adopt modular design, and the components are highly versatile, which is easy to maintain and replace, reducing downtime.

Stable operation and high efficiency

Precise design, good dynamic balance, low vibration and low noise during pump operation, suitable for long-term continuous operation, ensuring the stability of chemical production.

Diversified selection, strong adaptability

Self-priming, magnetic drive, diaphragm pumps and other forms can be selected according to different working conditions to meet different viscosity, temperature, pressure and other conditions.

Excellent safety protection performance

Some chemical pumps are equipped with safety functions such as leakage monitoring, dry operation protection, and high temperature sealing system to ensure the safety of operators and equipment.

Wide application field

Petrochemical: Conveying various hydrocarbons, organic solvents, and corrosive fluids is the core component of refining, polymerization, and reaction devices.

Fine chemicals and pharmaceuticals: used for high-purity material transmission to meet the strict requirements of hygiene and sealing.

Water treatment and environmental protection engineering: Conveying high-concentration acid and alkali liquids, waste liquids or desalination solutions is an indispensable part of sewage treatment equipment.

Food and beverage industry: Use sanitary chemical pumps to convey food-grade liquids such as syrup, alcohol, and additives.

Electroplating and dyeing industry: Acid-resistant pumps and alkali-resistant pumps are used for the circulation and transportation of electrolytes and dyes.

Technology Development Trends

With the development of green chemical industry and intelligent manufacturing, Chemical Process Pumps are also constantly upgrading towards a smarter, more efficient and environmentally friendly direction:

Intelligent monitoring system: integrated pressure, temperature, vibration, and flow sensors to achieve remote monitoring and early warning of the pump status.

Energy-saving optimization design: CFD fluid simulation is used to optimize the flow channel, improve efficiency, and reduce energy consumption.

Leak-free magnetic drive pump: replaces traditional mechanical seal pumps, solves the problem of toxic and flammable fluid leakage, and improves the safety level.

Development of new corrosion-resistant materials: such as duplex stainless steel, ceramics, ETFE coatings, etc., to provide higher corrosion protection for pumps.

Chemical Process Pumps are the real "heart" of the chemical system, carrying multiple tasks such as liquid transportation, energy conversion, and safety protection. In the context of increasing attention to production efficiency and environmental safety today, high-quality chemical process pumps can not only greatly improve the process level, but also effectively reduce energy consumption and operating costs. With the advancement of Industry 4.0, technological innovation in this field will continue to promote the chemical industry to move towards intelligence and greening.

en

en  русский

русский Español

Español