CZ Standard Chemical Process Pump

Cat:Chemical Process Pump

1. Performance range of CZ type chemical pump (according to design point) Flow: Q 1.6-1500m3/h Lift: H 5-125m Working pressure: P less than or equal t...

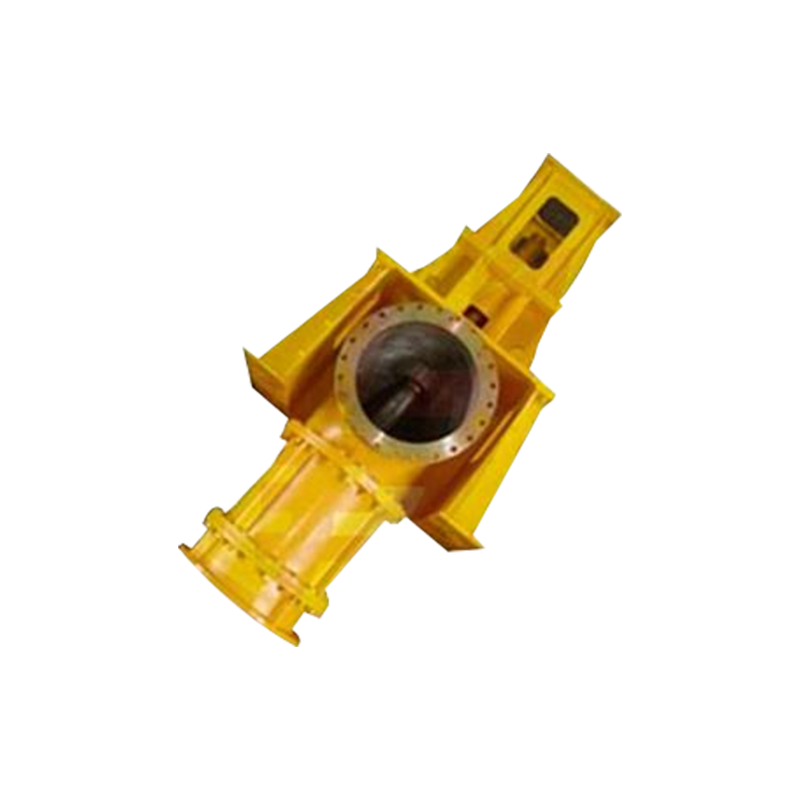

See DetailsIn modern high temperature energy systems, molten salt is increasingly used as a heat transfer and energy storage medium, especially in solar thermal power generation, nuclear energy, chemical industry and energy storage. In order to efficiently transport this high temperature, high density and corrosive medium, molten salt axial flow pumps came into being and became an important equipment to ensure the safe and efficient operation of the system. This article will conduct an in-depth analysis of the working principle, technical advantages, application fields and challenges of molten salt axial flow pumps.

Technical advantages

Efficient and large flow delivery: Axial flow pumps can maintain high efficiency when handling large volume and high temperature molten salt, and are suitable for rapid circulation in thermal energy conversion systems.

Compact structure and convenient maintenance: Compared with other pump types, axial flow pumps have a simpler structure, which is convenient for maintenance and replacement of parts, reducing system downtime.

Strong adaptability: A variety of sizes and impeller structures can be customized to adapt to different system head and flow requirements.

High temperature adaptability: specially designed heat-resistant alloy materials and shaft sealing systems enable it to operate stably for a long time in extremely high temperature environments.

Solar thermal power generation (CSP) system: molten salt is used for energy storage and heat transfer, and the axial flow pump is responsible for efficiently transporting molten salt between heat exchangers, storage tanks and tower collectors.

Fourth-generation nuclear reactors: such as sodium-cooled fast reactors or molten salt reactors, molten salt is used as a coolant or fuel carrier, and the axial flow pump plays a role in circulation promotion.

Molten salt energy storage system (MSES): When adjusting the load between renewable energy and the power grid, the axial flow pump is used to achieve rapid conversion and release of molten salt thermal energy.

Chemical and metallurgical industries: Molten salt axial flow pumps are also commonly used in scenarios where high-temperature salts, liquid metals or other corrosive liquids are transported.

Material life and corrosion issues: molten salt often contains chlorides and fluorides, which place extremely high demands on the corrosion resistance of the pump body material.

Start-stop condensation problem: once the molten salt is below the freezing point, it will crystallize rapidly, which may cause the pump body to be blocked, and an insulation and heating control system needs to be designed.

Complex sealing system: Conventional sealing technology is difficult to adapt to high temperature and high pressure environments, and special sealing designs such as magnetic drive are required.

Long-term stability verification: The test time of high-temperature pumps on the market is limited, and the stability and reliability of long-term operation still require a lot of engineering data verification.

With the continuous expansion of renewable energy and nuclear energy fields, the demand for molten salt axial flow pumps will continue to grow. Future research and development directions include new materials that are more corrosion-resistant, intelligent temperature control systems, more efficient pump body designs, and longer trouble-free operation life. Combined with digital monitoring and Internet of Things technology, the intelligence of molten salt pumps will also become an important trend, providing real-time data support and predictive maintenance capabilities for system operation.

As a key component connecting high-temperature energy media and heat energy conversion equipment, molten salt axial flow pumps are playing an irreplaceable role in major high-temperature systems. Faced with extreme environments and high-performance requirements, its technological development not only reflects breakthroughs in engineering manufacturing, but also indicates the continuous improvement of clean energy utilization capabilities. As technology continues to mature, molten salt axial flow pumps will play a more critical role in the future energy structure.