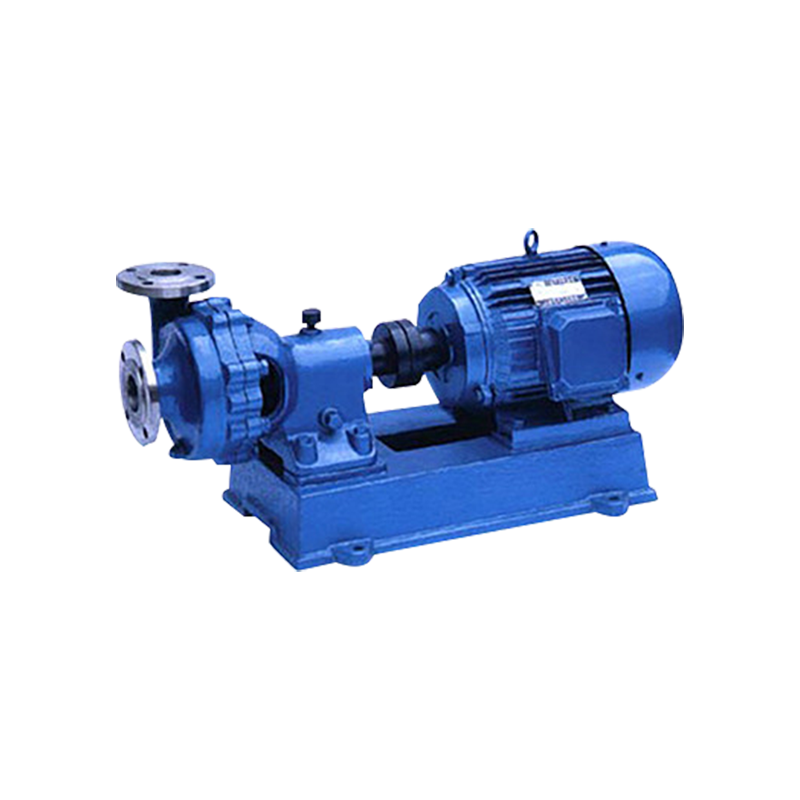

FSB Fluoroalloy Centrifugal Pump

Cat:Corrosion-Resistant Chemical Pump

FSB fluoroplastic pump overview FSB-type fluoroplastic alloy pump is designed according to international standard dimensions. The pump body is organic...

See DetailsChemical pumps are essential components in industries that involve the transfer of corrosive, flammable, or toxic liquids. These pumps are specifically engineered to withstand chemical attacks and ensure safe, reliable fluid handling in applications such as water treatment, pharmaceuticals, petrochemicals, and food processing. While there are many pump designs available, three major types dominate chemical handling operations: Centrifugal Pumps, Diaphragm Pumps, and Magnetic Drive Pumps. Each type serves unique operational needs based on fluid properties, system pressure, and flow requirements.

1. Centrifugal Chemical Pumps

Centrifugal pumps are the most commonly used type in chemical processing. They operate by using a rotating impeller to generate centrifugal force, which moves fluid through the pump casing and into the discharge line.

Key Features:

Ideal for low-viscosity fluids such as acids, solvents, and water-like chemicals

Provide high flow rates with relatively smooth and continuous discharge

Simple design makes them easy to maintain and cost-effective

Applications:

Industrial chemical transfer

Cooling water circulation

Acid handling in water treatment plants

Centrifugal chemical pumps are often made from corrosion-resistant materials such as polypropylene, PVDF, stainless steel, or FRP composites.

2. Diaphragm Chemical Pumps

Diaphragm pumps, also known as air-operated double diaphragm (AODD) pumps, use a reciprocating diaphragm to draw and push fluids. They are positive displacement pumps, making them suitable for dosing, metering, or transferring fluids with high viscosity or particulates.

Key Features:

Self-priming and capable of dry running without damage

Ideal for hazardous, abrasive, or slurry-type chemicals

Leak-free operation due to no dynamic seals

Applications:

Transferring viscous chemical slurries

Metering acids or alkaline solutions

Handling aggressive or hazardous fluids in remote or mobile setups

Their versatility makes diaphragm pumps highly popular in chemical manufacturing, mining, and wastewater treatment.

3. Magnetic Drive Chemical Pumps

Magnetic drive pumps (or mag-drive pumps) are seal-less centrifugal pumps that use magnetic coupling instead of mechanical seals, preventing any leakage of hazardous liquids.

Key Features:

Leak-free design—no risk of seal failure

Ideal for toxic, flammable, or environmentally hazardous chemicals

Low maintenance due to fewer moving parts

Applications:

Transferring solvents or hydrocarbons in chemical plants

Circulation of acids in semiconductor or electronic manufacturing

Applications requiring zero leakage tolerance

Mag-drive pumps are perfect for operations where environmental safety, operator protection, and chemical containment are critical.

By understanding these three core types of chemical pumps, engineers and procurement teams can make informed decisions that enhance process safety, reliability, and efficiency in any chemical-handling application.