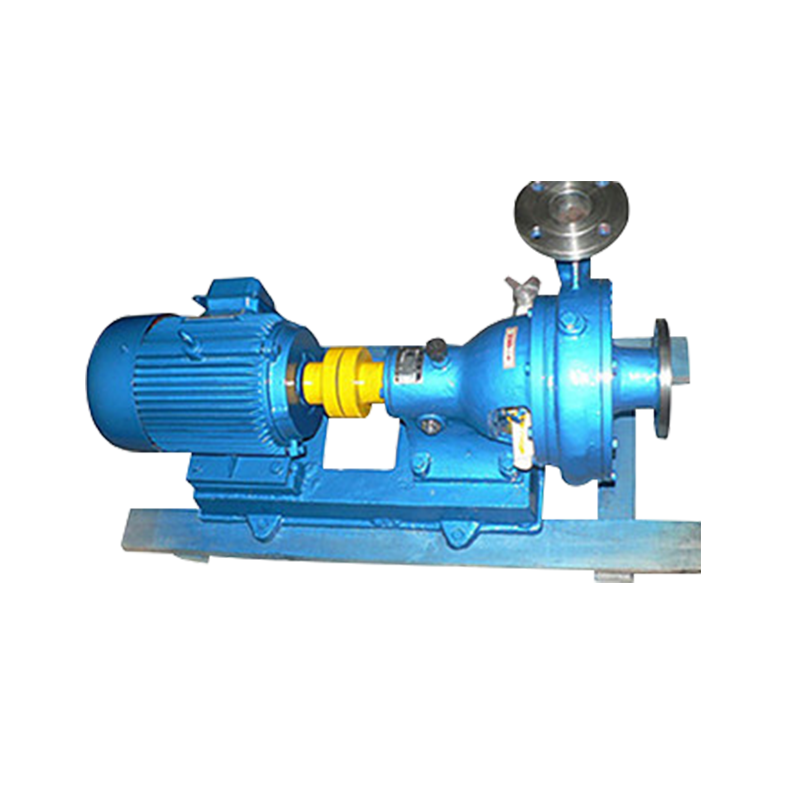

IH Type Horizontal Chemical Centrifugal Pump

Cat:Chemical Process Pump

The IH type chemical centrifugal pump is a single-stage single-suction (axial suction) cantilever centrifugal pump, which is used to transport liquids...

See DetailsChemical sewage pumps are specialized pumping devices designed to handle corrosive, abrasive, and chemically aggressive wastewater. Unlike standard pumps, these pumps are engineered with materials and structural features that allow safe and efficient transfer of harsh industrial effluents, chemical-laden wastewater, and other aggressive fluids. They are widely used in chemical processing, wastewater treatment, pharmaceutical, and food manufacturing facilities.

Their advanced design ensures durability, minimizes maintenance, and improves operational safety, providing critical advantages over conventional pumping solutions.

Chemical sewage pumps are typically constructed from high-grade materials such as stainless steel, polypropylene, PVDF (polyvinylidene fluoride), or other corrosion-resistant alloys. These materials prevent chemical degradation that standard metal or plastic pumps may face when exposed to acids, alkalis, or aggressive chemicals.

Corrosion resistance ensures a longer service life, reduces unplanned downtime, and eliminates the need for frequent component replacements, which is common in conventional pumps handling chemical wastewater.

Chemical sewage pumps are designed to manage not only corrosive liquids but also fluids containing suspended solids, sludge, or abrasive particles. Special impeller designs, such as semi-open or vortex types, allow these pumps to transfer viscous or particle-laden wastewater without clogging or excessive wear.

This capability provides a significant advantage over standard pumps, which often experience frequent blockages and accelerated component erosion when handling abrasive slurries or industrial effluents.

Chemical sewage pumps are engineered for high hydraulic efficiency, ensuring consistent flow rates and reliable performance under varying conditions. Their robust construction and optimized impeller design allow for smooth fluid transfer even in challenging chemical environments.

Compared to standard pumps, these specialized pumps maintain efficiency despite corrosive or abrasive fluids, reducing energy consumption and minimizing operational costs over the lifespan of the system.

Chemical sewage pumps are designed to minimize maintenance needs, thanks to their durable materials and wear-resistant components. Unlike standard pumps, they often feature mechanical seals or magnetic drive systems that prevent leaks and contamination.

Lower maintenance translates to higher productivity, lower operational cost, and fewer disruptions in industrial processes.

Chemical sewage pumps are designed with safety and environmental protection in mind. Materials used in construction prevent chemical leaks that could harm operators or contaminate the environment. Enclosed pump designs and corrosion-resistant seals ensure that hazardous fluids are safely contained during operation.

Additionally, these pumps help facilities meet regulatory compliance standards for wastewater handling and chemical transport, which is crucial in chemical and industrial sectors.

Chemical sewage pumps are highly versatile, capable of handling a wide range of industrial fluids, including acids, alkalis, solvents, slurries, and waste streams with high solid content. Their adaptability makes them suitable for multiple industries:

This versatility ensures that one pump model can meet a variety of operational needs, reducing the number of specialized units required.

| Feature | Chemical Sewage Pump | Standard Pump |

| Corrosion Resistance | High | Low |

| Abrasive Fluid Handling | Yes | Limited |

| Maintenance Frequency | Low | High |

| Safety for Operators | High | Moderate |

| Lifespan | Long | Moderate |

Chemical sewage pumps provide superior corrosion resistance, ability to handle abrasive and viscous fluids, high efficiency, reduced maintenance, and enhanced safety compared to standard pumps. These advantages make them indispensable in modern industrial wastewater treatment and chemical processing applications.

Investing in chemical sewage pumps ensures operational reliability, lower long-term costs, and compliance with safety and environmental regulations, offering both practical and strategic benefits to industrial operators.