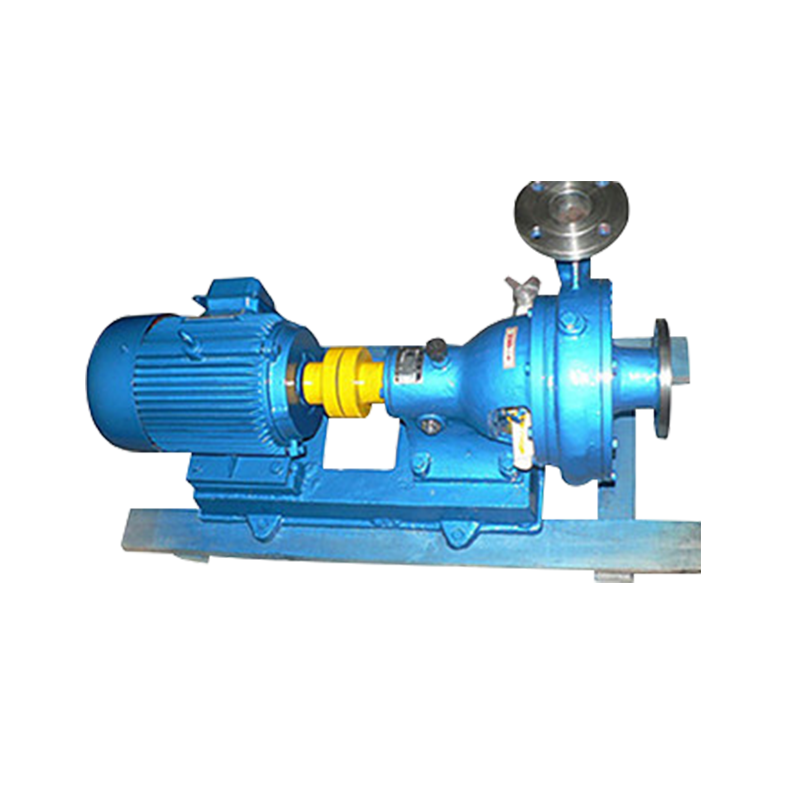

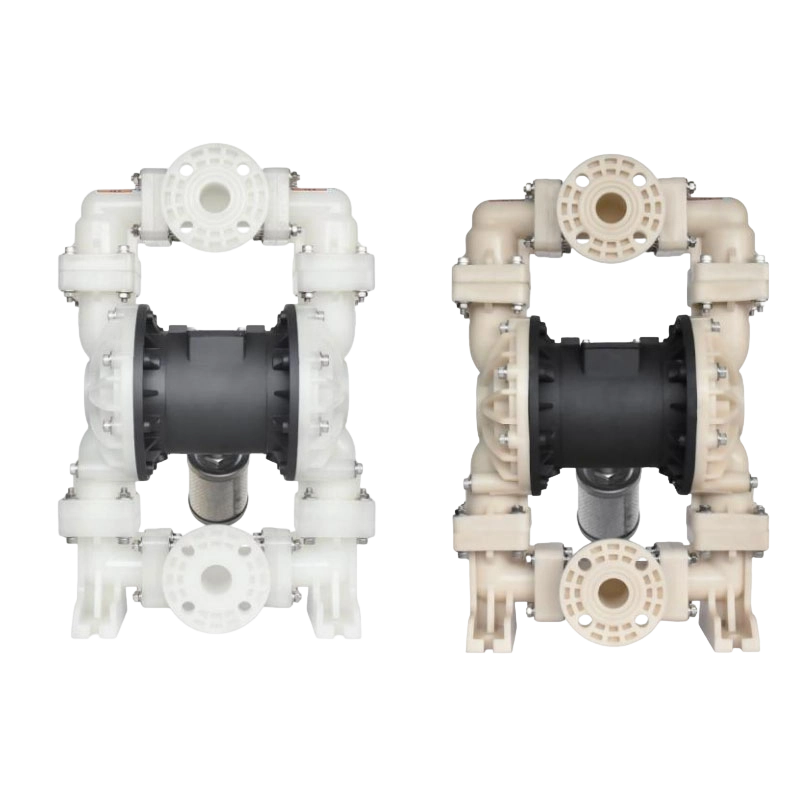

High temperature chemical pumps are engineered to handle fluids at elevated temperatures, which are commonly encountered in chemical processing, petrochemical, and energy industries. Unlike standard chemical pumps, these specialized pumps are designed to resist thermal stresses, maintain structural integrity, and ensure reliable performance in demanding conditions. Understanding their design, applications, and advantages is crucial for selecting the right pump for industrial operations.

Key Differences in Materials and Construction

Materials Resistant to Heat and Corrosion

High temperature chemical pumps use materials such as stainless steel alloys, Hastelloy, Inconel, or specialized ceramics that can withstand both high temperatures and corrosive chemicals. Standard pumps often rely on conventional stainless steel or cast iron, which may deform or corrode under extreme heat. The choice of material ensures longevity and minimal maintenance.

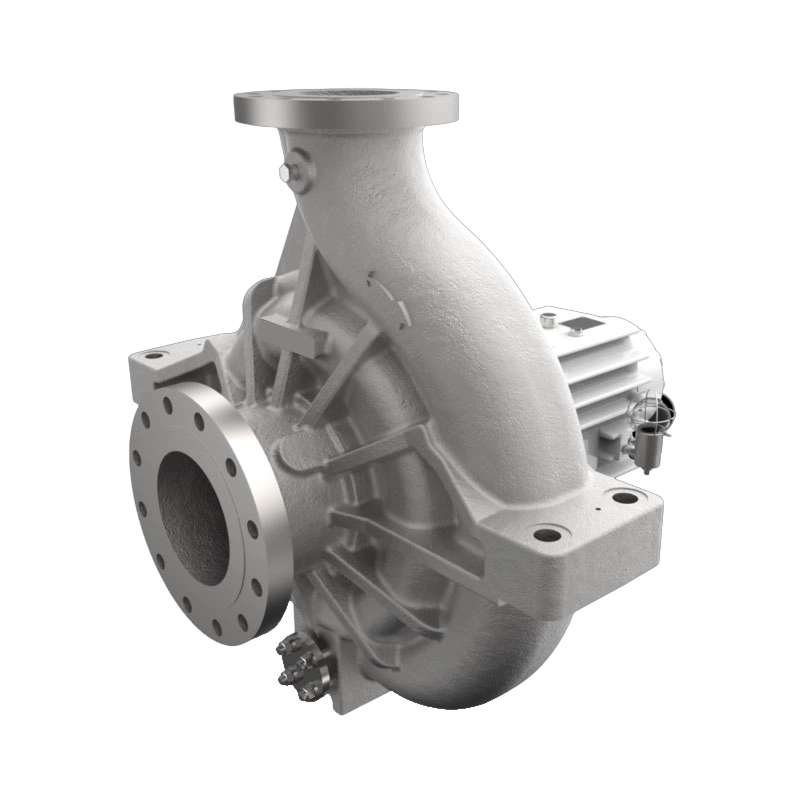

Enhanced Mechanical Design

The mechanical components of high temperature pumps, including shafts, bearings, and seals, are optimized to handle thermal expansion. These pumps often use high-temperature gaskets, mechanical seals with advanced sealing faces, and precision-engineered shafts to prevent leakage and maintain consistent operation. In contrast, standard chemical pumps may fail under prolonged heat exposure.

Performance Characteristics

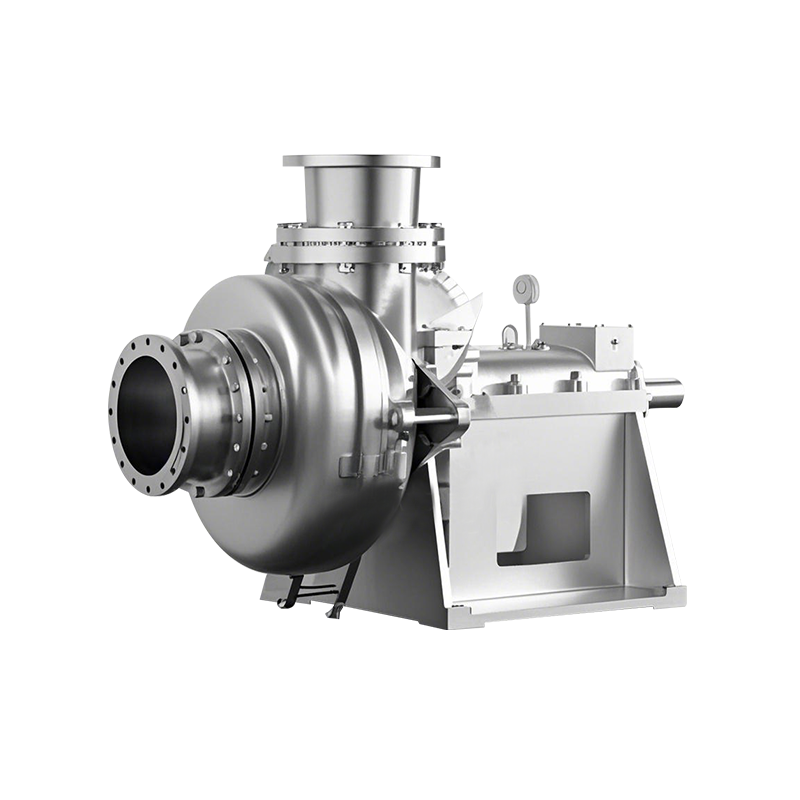

Flow Rate and Pressure Capabilities

High temperature pumps are designed to maintain consistent flow rates and pressure even when fluid viscosity changes with temperature. They often incorporate impellers and casings that minimize turbulence and energy loss. Standard pumps, without such optimizations, may experience reduced efficiency or cavitation when handling hot fluids.

Thermal Management

These pumps may feature cooling jackets, heat shields, or insulation to protect internal components from excessive heat. Such measures are generally absent in standard pumps, making them unsuitable for prolonged high-temperature operation.

Applications in Industry

Chemical Processing Plants

High temperature chemical pumps are essential in chemical plants for transferring acids, alkalis, and other reactive chemicals at elevated temperatures. They ensure safety, minimize downtime, and maintain process efficiency.

Petrochemical and Refining Operations

In petrochemical industries, these pumps handle hot hydrocarbons, steam, and viscous fluids. Their robust construction prevents failure in operations involving high-pressure and high-temperature fluids.

Power Generation and Thermal Systems

Power plants and thermal systems use high temperature chemical pumps to circulate hot water, oil, or molten salts. Their ability to operate continuously at high temperatures is critical for energy efficiency and system reliability.

Advantages Over Standard Pumps

- Can handle fluids at temperatures exceeding 200°C without compromising performance.

- Superior resistance to thermal fatigue and corrosion, increasing operational lifespan.

- Reduced risk of leakage due to advanced mechanical seals and thermal management.

- Maintains consistent flow and pressure despite changes in fluid properties.

- Minimizes downtime and maintenance costs in demanding industrial environments.

Selection Criteria

Temperature and Pressure Ratings

Choosing the correct pump requires understanding the maximum operating temperature and pressure of the system. Pumps must be rated above the expected operating conditions to ensure safety and reliability.

Material Compatibility

The selected pump material must be compatible with the chemical properties of the fluid to prevent corrosion or degradation. Consulting chemical resistance charts is critical.

Maintenance and Reliability

High temperature pumps require scheduled inspections, particularly of seals and bearings. Choosing pumps with modular components can simplify maintenance and reduce operational downtime.

Conclusion

High temperature chemical pumps differ from standard pumps primarily in materials, mechanical design, and thermal management. They are indispensable in industries where fluids are handled at elevated temperatures, offering enhanced reliability, safety, and efficiency. Selecting the right pump involves careful consideration of temperature, pressure, material compatibility, and maintenance requirements to ensure optimal performance in demanding industrial applications.

en

en  русский

русский Español

Español