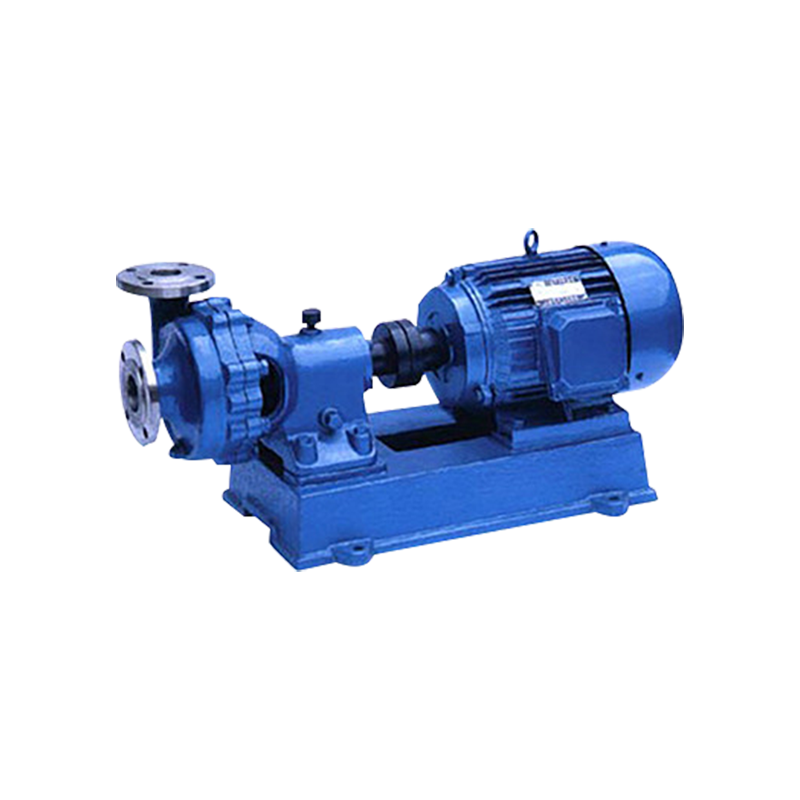

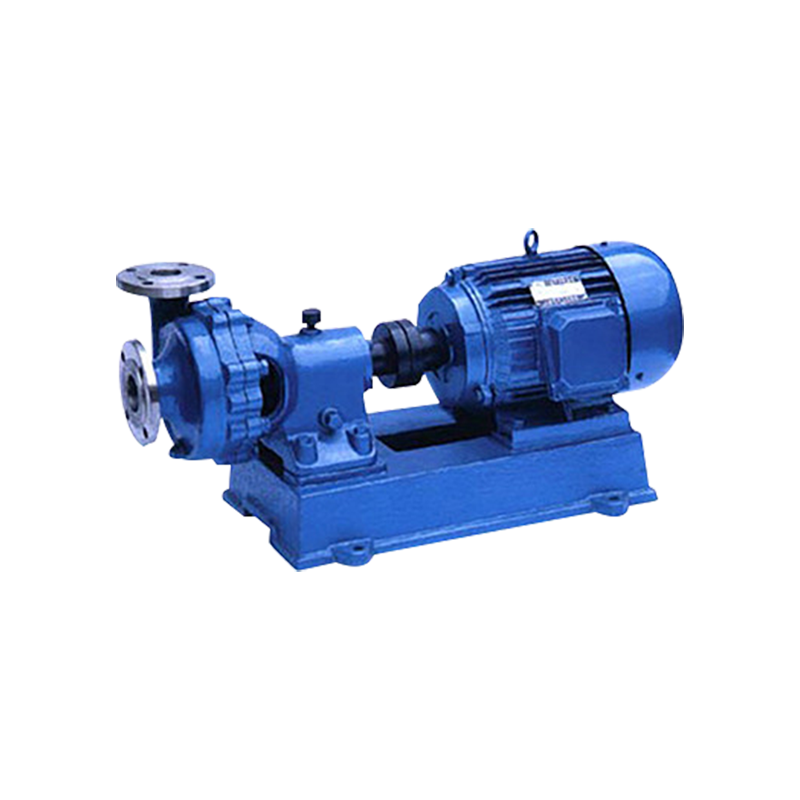

Chemical pumps are critical components in industrial processes, responsible for the safe and efficient transfer of liquids, often under demanding conditions. Unlike standard water pumps, chemical pumps handle corrosive, abrasive, and volatile fluids, making their maintenance both vital and challenging. High-performance chemical pumps—used in industries such as chemical manufacturing, pharmaceuticals, wastewater treatment, and petrochemicals—require a well-structured maintenance program to ensure reliability, efficiency, and safety.

This article explores essential maintenance practices for high-performance chemical pumps, emphasizing routine inspection, preventive measures, and proper operation techniques to extend service life and minimize downtime.

1. Understand the Importance of Maintenance

Chemical pumps often operate under harsh conditions, including high temperatures, pressures, and exposure to corrosive or abrasive fluids. Without proper maintenance:

- Efficiency declines due to wear and tear on impellers and seals.

- Downtime increases, leading to costly production interruptions.

- Safety risks escalate, especially when handling hazardous chemicals.

- Operating costs rise, as poorly maintained pumps consume more energy and require frequent replacements.

A comprehensive maintenance strategy not only protects the pump but also ensures consistent performance and safety compliance.

2. Establish a Routine Inspection Schedule

Regular inspections are the backbone of chemical pump maintenance. Key inspection steps include:

- Visual Inspection: Check for leaks, corrosion, or unusual wear on pump housing, fittings, and connections.

- Alignment Check: Misaligned pump shafts or couplings can cause vibration, noise, and premature bearing failure.

- Seal Examination: Mechanical seals, gaskets, and O-rings should be inspected for leaks or cracks.

- Impeller Condition: Look for erosion, pitting, or blockage that can reduce flow efficiency.

- Lubrication Levels: Bearings and gear components should be properly lubricated according to manufacturer specifications.

Documenting these inspections in a maintenance log allows operators to identify trends and address potential issues before they escalate.

3. Prioritize Preventive Maintenance

Preventive maintenance reduces the likelihood of unexpected failures and extends pump life. Essential practices include:

- Lubrication: Bearings, gears, and other moving components must be lubricated regularly. Use the lubricant recommended by the manufacturer to avoid chemical incompatibility.

- Seal Replacement: Mechanical seals should be replaced periodically, even if they appear functional, to prevent leaks of hazardous fluids.

- Bearing Checks: Inspect and replace bearings showing signs of wear or overheating.

- Impeller Cleaning: Remove accumulated debris and scale to maintain flow efficiency.

- Coupling Inspection: Ensure couplings are not worn or misaligned, which can cause vibration and energy loss.

Implementing preventive measures helps maintain operational efficiency and reduces the frequency of costly repairs.

4. Monitor Operating Conditions

Operating conditions have a direct impact on pump performance and lifespan. Critical factors to monitor include:

- Flow Rate and Pressure: Deviations from design specifications can indicate blockages, impeller damage, or other issues.

- Temperature: Excessive temperatures can damage seals, bearings, and pump casings.

- Vibration Levels: Unusual vibrations may signal misalignment, imbalance, or worn components.

- Noise Levels: Unusual noise often indicates cavitation, air pockets, or mechanical issues.

Advanced chemical pumps may include sensors for real-time monitoring of flow, pressure, and temperature, allowing proactive maintenance interventions.

5. Proper Handling of Chemical Fluids

Chemical pumps are often exposed to aggressive fluids that can accelerate wear. Correct handling practices help preserve pump integrity:

- Material Compatibility: Ensure pump components (e.g., impellers, seals, casings) are compatible with the chemicals being pumped. Common materials include stainless steel, PTFE, Hastelloy, and other corrosion-resistant alloys.

- Avoid Dry Running: Pumps should never run dry, as this can damage seals, bearings, and impellers.

- Proper Start-Up and Shut-Down Procedures: Follow manufacturer-recommended procedures to prevent hydraulic shock and sudden temperature spikes.

- Filtration: Installing strainers or filters prevents abrasive particles from entering the pump, reducing impeller erosion and wear.

By managing the chemical fluid correctly, operators can significantly extend pump life and reduce maintenance costs.

6. Implement Cleaning and Flushing Practices

Residue and scale buildup inside the pump can impair performance and increase wear:

- Periodic Flushing: Use compatible solvents or water to flush residual chemicals from the pump.

- Cleaning Internal Components: Impellers, casings, and piping should be cleaned to prevent clogging and erosion.

- Prevent Corrosion: Ensure that post-flushing, the pump is dried and protected to avoid rust or corrosion.

Routine cleaning not only maintains efficiency but also ensures chemical safety compliance.

7. Record-Keeping and Maintenance Logs

Maintaining detailed logs of maintenance activities, inspections, and repairs provides several benefits:

- Trend Analysis: Identifying recurring issues helps predict failures and plan proactive interventions.

- Compliance: Documentation supports regulatory compliance in industries handling hazardous chemicals.

- Asset Management: Logs help track pump life cycles, making it easier to schedule replacements or upgrades.

Digital maintenance systems and CMMS (Computerized Maintenance Management Systems) can further streamline this process.

8. Troubleshooting Common Issues

Even with routine maintenance, chemical pumps may experience problems. Understanding common issues and corrective actions is critical:

- Leakage: Often caused by worn seals or gaskets. Replace faulty components and ensure proper alignment.

- Cavitation: Occurs when vapor bubbles form and collapse inside the pump. Reduce suction lift, increase NPSH (Net Positive Suction Head), or lower fluid temperature.

- Excessive Vibration: Check alignment, balance impellers, and inspect bearings.

- Reduced Flow: May result from clogging, worn impellers, or air in the system. Clear blockages, replace damaged parts, and purge air.

- Overheating: Can be due to dry running, high viscosity fluids, or bearing failure. Monitor operating conditions and maintain proper lubrication.

Timely troubleshooting prevents minor issues from turning into major failures.

9. Staff Training and Standard Operating Procedures

Even the best maintenance plan can fail without skilled personnel:

- Operator Training: Ensure staff understand correct pump operation, start-up/shutdown procedures, and emergency responses.

- Maintenance SOPs: Develop and enforce standard operating procedures for inspection, cleaning, lubrication, and part replacement.

- Safety Protocols: Chemical pumps often handle hazardous fluids; proper PPE, spill containment, and safety measures are critical.

Training and SOPs improve maintenance consistency and reduce human error.

10. Investing in Quality Spare Parts and Upgrades

Using high-quality components is essential for maintenance efficiency:

- OEM Parts: Prefer original equipment manufacturer parts for seals, bearings, and impellers to ensure compatibility.

- Upgraded Materials: Consider corrosion-resistant alloys or enhanced coatings to extend component life.

- Modern Sensors: Installing flow, pressure, and temperature sensors enables predictive maintenance and reduces unexpected downtime.

Investing in quality parts and technology reduces long-term maintenance costs.

Conclusion

High-performance chemical pumps are critical assets in industrial operations, and their reliability depends heavily on proper maintenance. Essential practices include regular inspections, preventive maintenance, monitoring operating conditions, correct chemical handling, cleaning, and detailed record-keeping.

Understanding common issues, providing staff training, and using quality spare parts further ensure optimal performance and longevity. By implementing a comprehensive maintenance strategy, industries can achieve consistent efficiency, reduce operational costs, and maintain a safe working environment while maximizing the lifespan of chemical pumps.

A well-maintained chemical pump not only safeguards production continuity but also protects personnel and the environment from the risks associated with hazardous chemicals. Investing in proper maintenance is therefore both a practical and strategic choice for any industrial operation.