Screw pumps are widely used in industries such as oil and gas, food processing, chemical, and wastewater treatment, where they efficiently handle viscous liquids, slurries, and abrasive fluids. At the heart of these pumps is the stator, a stationary component that works together with the rotor to move fluid through the pump chamber. The stator’s performance directly influences pump efficiency, flow consistency, and longevity.

However, like any mechanical component, screw pump stators can experience various issues that affect overall performance. Understanding these common problems and troubleshooting methods is crucial for maintenance personnel and operators to ensure reliable operation and reduce downtime.

1. Understanding the Role of a Screw Pump Stator

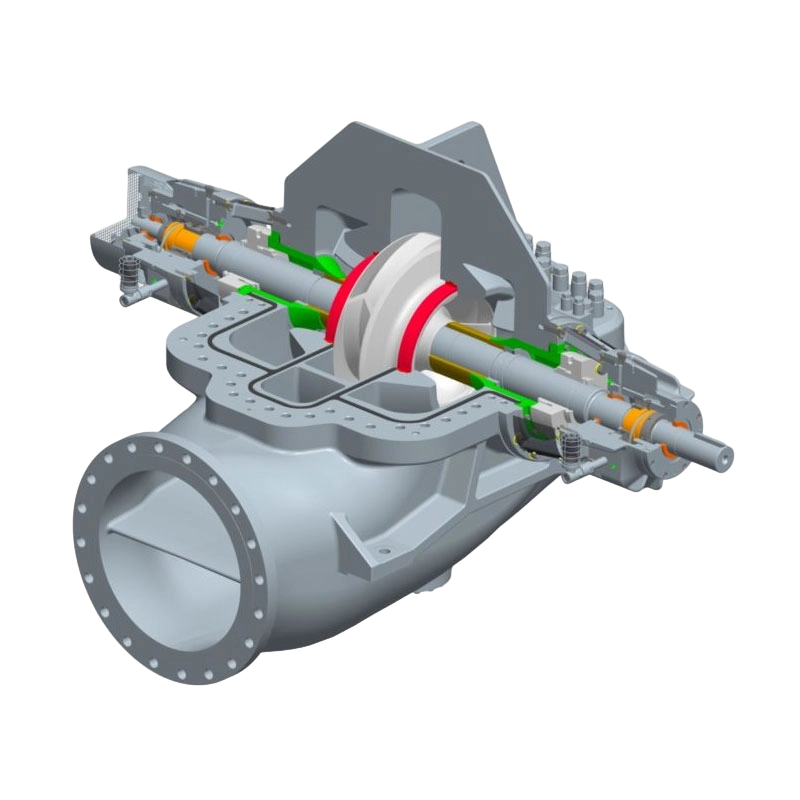

A screw pump generally consists of a rotor, a stator, and a pump housing:

- The rotor is a helical element that rotates inside the stator.

- The stator is typically made of elastomeric material, such as rubber, nitrile, or silicone, which forms a tight seal with the rotor.

- Together, the rotor and stator create sealed cavities that move the fluid from the suction to the discharge side of the pump.

The stator’s design and material are critical because it must withstand:

- High pressures and torque

- Abrasion from particulates in the fluid

- Chemical exposure

- High operating temperatures

Proper operation of the stator ensures smooth, pulse-free flow and maximum pump efficiency.

2. Common Issues with Screw Pump Stators

2.1 Wear and Tear

Problem:

Over time, stators experience mechanical wear due to constant contact with the rotor and abrasive particles in the fluid. This wear can cause:

- Reduced sealing efficiency

- Loss of pumping pressure

- Increased fluid slip

Causes:

- Pumping fluids with high sand or particulate content

- Excessive rotor speed

- Improper material selection for the pumped fluid

Troubleshooting:

- Inspect stator surfaces regularly for signs of wear or thinning.

- Replace the stator if wall thickness is compromised.

- Consider upgrading to more abrasion-resistant elastomers for fluids with high particulate content.

2.2 Swelling or Shrinking

Problem:

Stators made of elastomers can swell or shrink due to chemical reactions, high temperatures, or prolonged exposure to incompatible fluids.

Symptoms:

- Difficulty rotating the rotor

- Reduced flow rate or pump efficiency

- Premature wear

Causes:

- Pumping hydrocarbons, solvents, or aggressive chemicals incompatible with stator material

- Exposure to temperatures outside the stator’s recommended range

Troubleshooting:

- Select stator materials compatible with the pumped fluid (e.g., nitrile for oils, EPDM for water-based solutions).

- Monitor operating temperatures and avoid exceeding material limits.

- Replace stators showing significant swelling or deformation.

2.3 Cavitation Damage

Problem:

Cavitation occurs when vapor bubbles form and collapse inside the pump, leading to localized damage to the stator.

Symptoms:

- Pitting on stator surfaces

- Noise and vibration during operation

- Decreased pump performance

Causes:

- Low suction pressure or high fluid temperature

- Improper pump sizing or flow rate

- Air entrainment in the fluid

Troubleshooting:

- Ensure the pump inlet is fully flooded and maintain adequate suction pressure.

- Check for leaks in suction lines and remove air traps.

- Adjust flow rate to within the pump’s recommended operating range.

2.4 Stator Dry Running

Problem:

Running a screw pump without fluid (dry running) causes extreme friction between the rotor and stator, leading to rapid wear or permanent damage.

Symptoms:

- Burned or scorched stator surface

- Rotor overheating

- Immediate loss of pump efficiency

Causes:

- Inadequate priming

- Sudden loss of suction supply

- Operator error or pump control failure

Troubleshooting:

- Always ensure the pump is properly primed before operation.

- Install dry-run protection sensors or flow switches to automatically stop the pump if no fluid is present.

- Inspect stator and rotor surfaces for damage before restarting.

2.5 Improper Installation

Problem:

Incorrect installation of the stator can lead to misalignment, uneven wear, and premature failure.

Symptoms:

- Unusual noise or vibration

- Uneven rotor movement

- Leaks at pump joints

Causes:

- Misaligned rotor and stator

- Incorrect stator length or compression

- Failure to follow manufacturer installation guidelines

Troubleshooting:

- Carefully follow the manufacturer’s installation instructions.

- Ensure the rotor and stator are properly aligned and seated.

- Verify correct stator compression and secure mounting.

2.6 Chemical Degradation

Problem:

Certain fluids may chemically react with the elastomer, leading to softening, cracking, or brittleness in the stator.

Symptoms:

- Flaking or peeling of stator surface

- Reduced sealing capability

- Premature failure

Causes:

- Pumping incompatible chemicals

- Exposure to strong acids, bases, or solvents

Troubleshooting:

- Select elastomers resistant to the specific chemicals being pumped (e.g., Viton for aggressive chemicals).

- Monitor for signs of chemical attack during routine inspections.

- Replace affected stators promptly to prevent rotor damage.

2.7 Overheating

Problem:

Excessive operating temperature can degrade the elastomer, causing loss of flexibility and reduced sealing efficiency.

Symptoms:

- Hardening or cracking of stator

- Reduced pumping efficiency

- Noise or vibration due to rotor-stator friction

Causes:

- Pumping fluids with high viscosity or temperature

- Insufficient cooling or ventilation

- Excessive rotor speed

Troubleshooting:

- Monitor fluid temperature and pump operating conditions.

- Ensure proper cooling and ambient ventilation.

- Use high-temperature elastomers if operating in extreme conditions.

3. Preventive Measures

Proactive maintenance and preventive measures can minimize stator problems and extend service life:

- Material Selection: Match stator elastomer with fluid type, temperature, and chemical compatibility.

- Proper Installation: Follow manufacturer guidelines for alignment, compression, and rotor-stator clearance.

- Routine Inspections: Check for wear, deformation, chemical attack, or overheating regularly.

- Lubrication and Priming: Ensure the pump is properly primed and lubricated to reduce friction and heat.

- Operating Conditions: Avoid running the pump outside recommended flow rates, pressures, or temperatures.

- Protective Systems: Install dry-run sensors, flow monitors, and temperature alarms to prevent accidental damage.

Preventive measures reduce downtime, maintenance costs, and the likelihood of catastrophic failure.

4. Conclusion

The stator is a critical component of screw pumps, directly influencing pump efficiency, reliability, and lifespan. Common issues associated with screw pump stators include:

- Wear and tear from abrasive fluids

- Swelling or shrinking due to chemical or thermal exposure

- Cavitation damage from vapor bubble collapse

- Dry running causing rapid wear and overheating

- Improper installation leading to misalignment and uneven wear

- Chemical degradation from incompatible fluids

- Overheating due to excessive friction or temperature

By understanding these problems and implementing appropriate troubleshooting and preventive measures, operators can maintain optimal pump performance, reduce downtime, and extend the service life of the stator and overall pump system.

Proper material selection, installation, monitoring, and maintenance are essential strategies for ensuring that screw pumps operate efficiently and reliably, even under challenging industrial conditions. With careful attention to these factors, screw pump stators can provide years of consistent, trouble-free service, making them a vital component in modern fluid handling operations.

en

en  русский

русский Español

Español