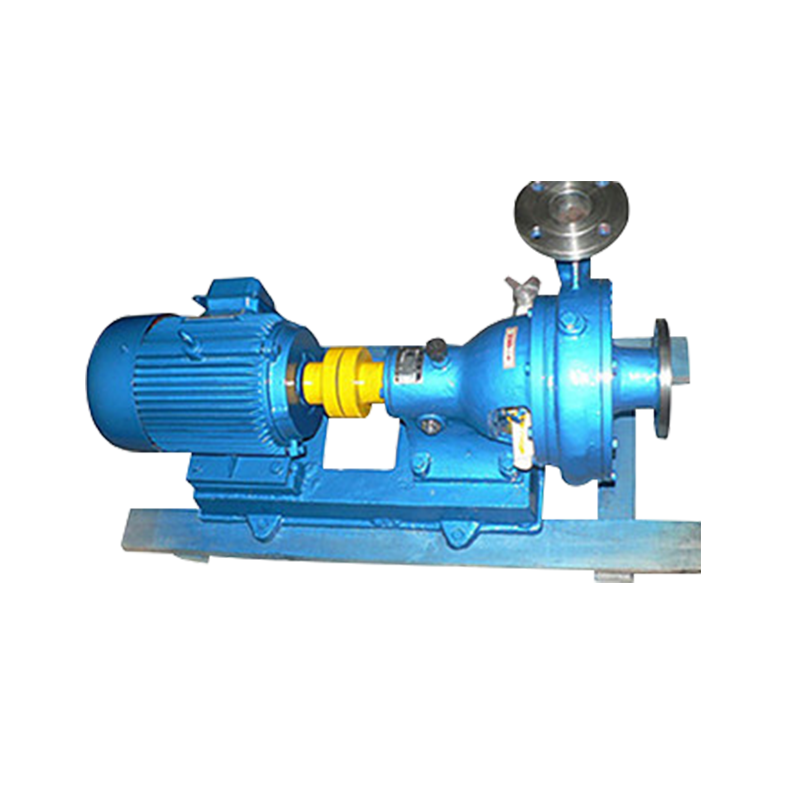

IJ Series Corrosion-Resistant Pump

Cat:Chemical Alkali Pump

IJ series corrosion-resistant pump is a single-stage, single-suction cantilever centrifugal pump. Its marking, rating characteristics, and dimensions ...

See DetailsChemical sewage pumps are specialized pumping systems designed to handle corrosive, abrasive, and contaminated wastewater containing chemicals, industrial effluents, and aggressive fluids. Unlike standard sewage pumps, these units are built with chemically resistant materials and robust sealing systems to ensure long-term reliability in harsh operating environments.

They are widely used in chemical plants, pharmaceutical facilities, electroplating workshops, wastewater treatment plants, and industrial processing facilities. Their primary function is to safely transport chemically contaminated sewage while preventing leakage, corrosion, and mechanical failure.

Chemical sewage pumps operate by converting mechanical energy from an electric motor into hydraulic energy to move contaminated fluids. The pump creates a pressure differential that draws chemical sewage into the inlet and discharges it through the outlet under controlled flow conditions.

Because chemical sewage often contains solids, corrosive agents, and variable pH levels, these pumps are engineered with specialized impellers, corrosion-resistant casings, and reinforced seals to maintain performance and prevent chemical attack.

Material selection is critical for chemical sewage pumps to ensure resistance against corrosion, erosion, and chemical degradation. The choice of material depends on the type of chemicals, temperature, and concentration levels in the sewage.

Different industrial environments require different pump designs to effectively handle chemical sewage. Each type offers unique advantages based on flow rate, head pressure, and chemical compatibility.

These pumps are designed to operate fully submerged in chemical sewage. They are commonly used in sump pits, collection tanks, and underground wastewater systems. Their sealed motor construction prevents chemical ingress and allows for efficient cooling.

Centrifugal pumps are widely used for continuous chemical sewage transfer. They are ideal for moderate to high flow rates and can be customized with corrosion-resistant impellers and casings.

Diaphragm pumps use a flexible membrane to move chemical sewage. They are well-suited for highly corrosive or hazardous fluids because they provide leak-free operation and precise flow control.

These pumps are used for chemical sewage with high viscosity and solid content. They provide smooth, low-shear pumping, making them suitable for sludge and chemically contaminated slurry.

Chemical sewage pumps are essential in many industries where wastewater contains aggressive chemicals or hazardous substances.

Selecting the correct chemical sewage pump requires careful evaluation of operational and chemical conditions to avoid premature failure and safety risks.

Proper installation is essential for safe and efficient operation of chemical sewage pumps. Incorrect installation can lead to leaks, vibration, and premature equipment failure.

Routine maintenance ensures long-term reliability and reduces the risk of chemical exposure and environmental contamination. Due to the hazardous nature of chemical sewage, safety protocols are critical.

Operators should regularly inspect seals, impellers, bearings, and casings for signs of wear, corrosion, or leakage. Preventive maintenance programs help identify issues before they lead to costly downtime or safety incidents.

Chemical sewage pumps play a critical role in safely managing corrosive and hazardous wastewater in industrial environments. Their specialized materials, sealing systems, and robust construction allow them to handle aggressive fluids while protecting personnel, equipment, and the environment.

By selecting the right pump type, ensuring chemical compatibility, and following best practices for installation and maintenance, industries can achieve reliable operation, reduce downtime, and improve overall safety and compliance.