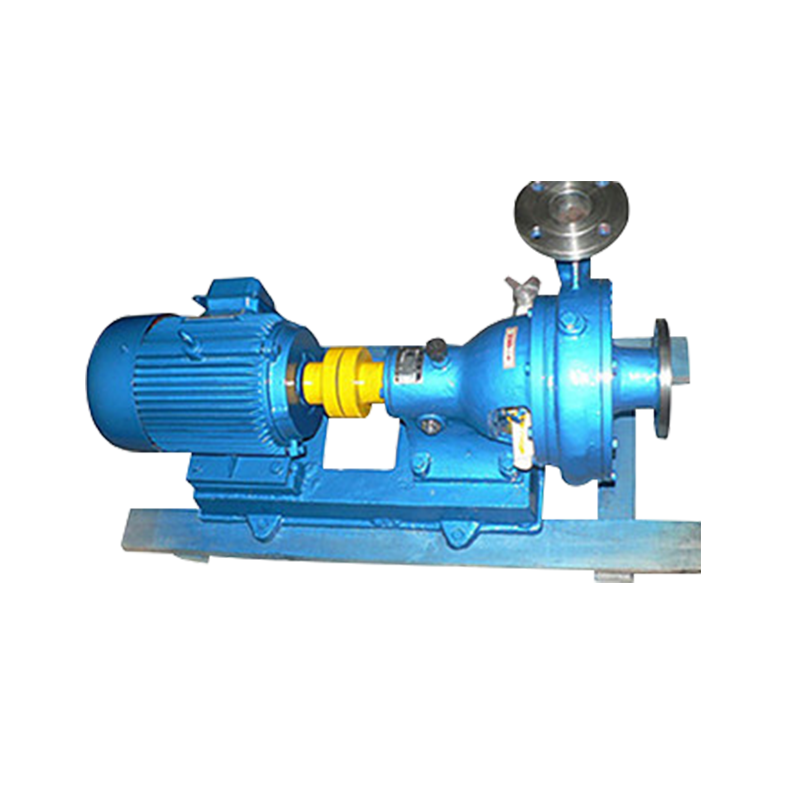

CZ Standard Chemical Process Pump

Cat:Chemical Process Pump

1. Performance range of CZ type chemical pump (according to design point) Flow: Q 1.6-1500m3/h Lift: H 5-125m Working pressure: P less than or equal t...

See DetailsIn industrial, municipal, and laboratory applications, the need to move corrosive, contaminated, or chemically aggressive liquids safely and efficiently is critical. This is where chemical sewage pumps play a pivotal role. But what exactly are chemical sewage pumps, how do they function, and why are they indispensable in modern fluid management systems?

What Are Chemical Sewage Pumps?

Chemical sewage pumps are mechanical devices designed to transport chemically aggressive and polluted liquids, often containing solids or abrasive particles, from one location to another. Unlike standard water pumps, these pumps are specifically engineered to withstand corrosion, chemical reactions, and abrasive wear, making them suitable for industries such as chemical processing, wastewater treatment, and pharmaceuticals.

These pumps handle liquids that may contain acids, alkalis, solvents, or other chemical contaminants that could quickly damage ordinary pumping equipment.

How Do Chemical Sewage Pumps Work?

The basic principle of a chemical sewage pump is similar to other centrifugal or positive displacement pumps:

Intake – The pump draws the liquid into the chamber.

Impeller or Piston Action – A rotating impeller or reciprocating piston moves the liquid forward, generating pressure.

Discharge – The liquid exits through the pump’s outlet, ready for further processing, treatment, or disposal.

What sets chemical sewage pumps apart is the materials used for the pump body, impeller, seals, and bearings, which are resistant to corrosion, abrasion, and chemical degradation.

Why Are Chemical Sewage Pumps Important?

Chemical sewage pumps are critical in industries where standard pumps would fail due to exposure to:

Corrosive chemicals – Acids, alkalis, and solvents that degrade metal and plastic components.

Abrasive solids – Sludge, sand, or particulate matter that causes wear.

Toxic or hazardous fluids – Preventing leaks is essential for safety and environmental compliance.

High-viscosity liquids – Ensuring smooth transfer without clogging.

By using chemical sewage pumps, industries ensure operational safety, reduce maintenance costs, and maintain continuous production processes.

What Materials Are Used in Chemical Sewage Pumps?

The choice of material is critical for durability and performance:

Stainless Steel (316, 304) – Excellent corrosion resistance, suitable for acids and alkaline solutions.

Hastelloy – High resistance to strong acids and aggressive chemicals.

PTFE (Teflon) Coatings – Provides chemical inertness and reduces friction.

Ceramic or Alloy Linings – Enhances abrasion resistance for sludge and solids.

High-Density Plastics (PP, PVDF) – Lightweight, corrosion-resistant options for less demanding applications.

Selecting the right material ensures long-lasting performance even under harsh chemical conditions.

How Are Chemical Sewage Pumps Classified?

Chemical sewage pumps can be categorized based on design and application:

Centrifugal Pumps – Use a rotating impeller to generate flow; suitable for low-viscosity liquids.

Positive Displacement Pumps – Include diaphragm, peristaltic, or piston designs; ideal for precise metering or handling viscous fluids.

Submersible Pumps – Can be submerged directly into the liquid, often used in sewage treatment.

Self-Priming Pumps – Capable of starting without pre-filling, convenient for intermittent use.

Each type offers advantages depending on the chemical composition, viscosity, and operational requirements of the liquid being pumped.

How Do Chemical Sewage Pumps Protect Against Corrosion and Wear?

Several design features enhance resistance to chemical attack:

Sealed Bearings and Shaft Seals – Prevent chemical leakage into mechanical components.

Corrosion-Resistant Coatings – Protect metal surfaces from acids and alkalis.

Hard Impellers and Linings – Reduce wear from abrasive particles in sewage or sludge.

Self-Cleaning Mechanisms – Minimize blockage and accumulation of solids.

These protective measures ensure that pumps maintain efficiency and longevity even in challenging environments.

Where Are Chemical Sewage Pumps Commonly Used?

Chemical sewage pumps are indispensable across multiple industries:

Wastewater Treatment Plants – Moving sludge and chemically treated water safely.

Chemical Processing Industries – Handling acids, bases, and reactive liquids.

Pharmaceutical Manufacturing – Transporting chemical mixtures and contaminated water.

Food and Beverage Industry – Managing cleaning solutions or chemical additives.

Mining and Metallurgy – Pumping slurry and acidic process liquids.

Their versatility makes them a cornerstone of safe and efficient fluid management.

How Do Chemical Sewage Pumps Enhance Operational Efficiency?

Continuous Operation – Designed to handle corrosive and abrasive fluids without frequent downtime.

Reduced Maintenance – Corrosion-resistant materials and robust design minimize wear and tear.

Energy Efficiency – Smooth hydraulic design reduces power consumption.

Improved Safety – Sealed and chemically resistant components prevent leaks and accidents.

Precision Flow Control – Certain models allow controlled dosing for industrial processes.

These benefits make chemical sewage pumps a reliable investment for industrial operators.

Are Chemical Sewage Pumps Safe to Operate?

Safety is a top priority when handling hazardous chemicals. Modern chemical sewage pumps incorporate:

Leak-Proof Seals – Prevent exposure to toxic liquids.

Automatic Shutoff Systems – Protect against overheating or dry running.

Corrosion-Resistant Components – Reduce the risk of structural failure.

Explosion-Proof Motors – Suitable for volatile chemical environments.

Operators can rely on these pumps to handle even aggressive fluids without compromising workplace safety.

How to Maintain a Chemical Sewage Pump?

Proper maintenance ensures consistent performance and extends lifespan:

Regular Inspection – Check seals, bearings, and impellers for wear or corrosion.

Cleaning – Remove sludge, sediment, and chemical residues to prevent clogging.

Lubrication – Maintain moving parts to reduce friction and wear.

Material Compatibility Checks – Ensure chemicals being pumped do not exceed the material limits.

Timely Replacement – Replace worn or damaged components to avoid failure.

Routine care enhances efficiency, safety, and reliability.

Final Thoughts: Why Are Chemical Sewage Pumps Essential?

Chemical sewage pumps are more than just industrial equipment—they are critical safeguards for processes involving corrosive, contaminated, or hazardous liquids. By combining robust materials, corrosion resistance, and precision design, these pumps ensure continuous operation, protect equipment, and maintain workplace safety.