In modern industrial production, the selection of liquid transportation equipment is directly related to production efficiency and safety. Especially in the chemical, pharmaceutical, electroplating, food, environmental protection and other industries, the media are mostly strong acids and alkalis, toxic and harmful or flammable and explosive substances, which put forward extremely high requirements on the corrosion resistance, sealing and stability of the pump equipment. At this time, Chemical Pumps has become the only choice for many companies.

Why choose chemical pumps?

1. Super strong corrosion resistance

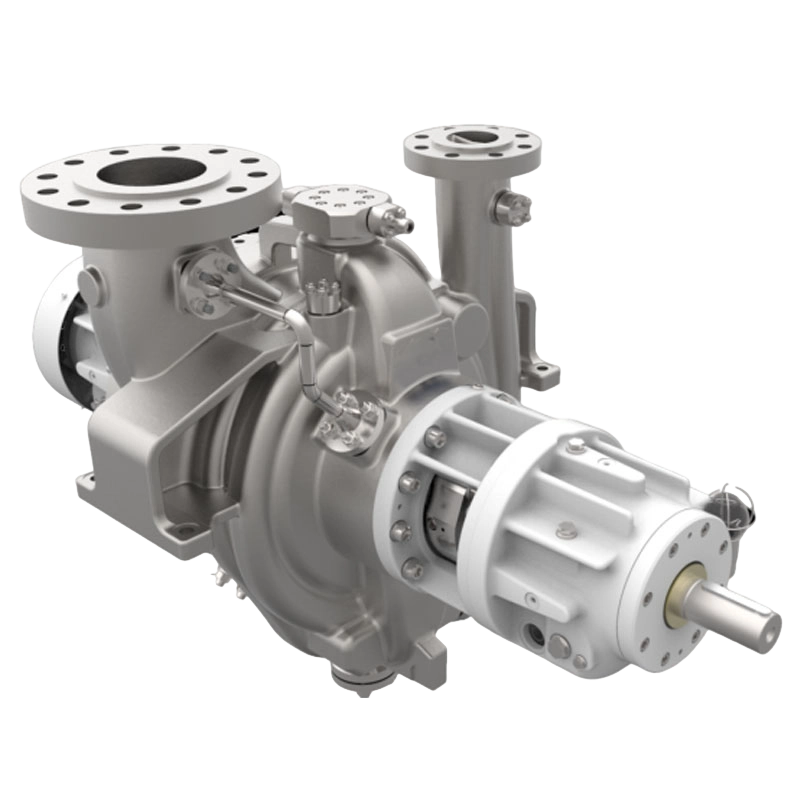

The biggest advantage of chemical pumps is their excellent corrosion resistance. Whether it is strong acid (such as sulfuric acid, hydrochloric acid) or strong alkali (such as sodium hydroxide, ammonia water), it can be safely transported without corroding the pump body, which fundamentally guarantees the life of the equipment and the safety of the operator.

2. Strong sealing and anti-leakage design

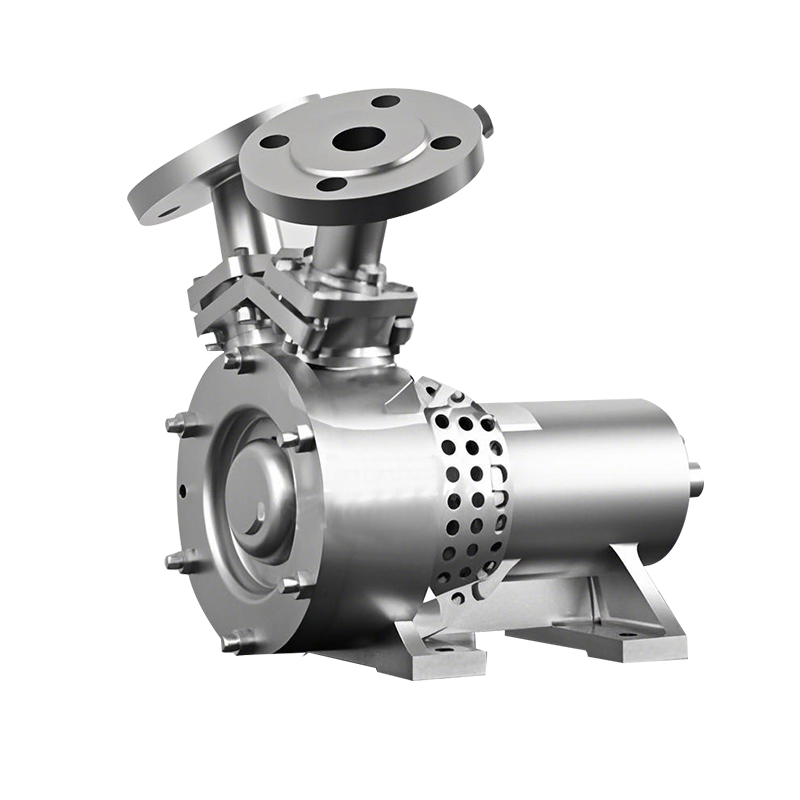

Since most of the conveying media are toxic or volatile liquids, chemical pumps usually adopt magnetic drive structure or high-grade mechanical seal design to completely eliminate liquid leakage, avoid environmental pollution and personal injury, and meet the dual requirements of environmental protection and safe production.

3. Compact structure and stable operation

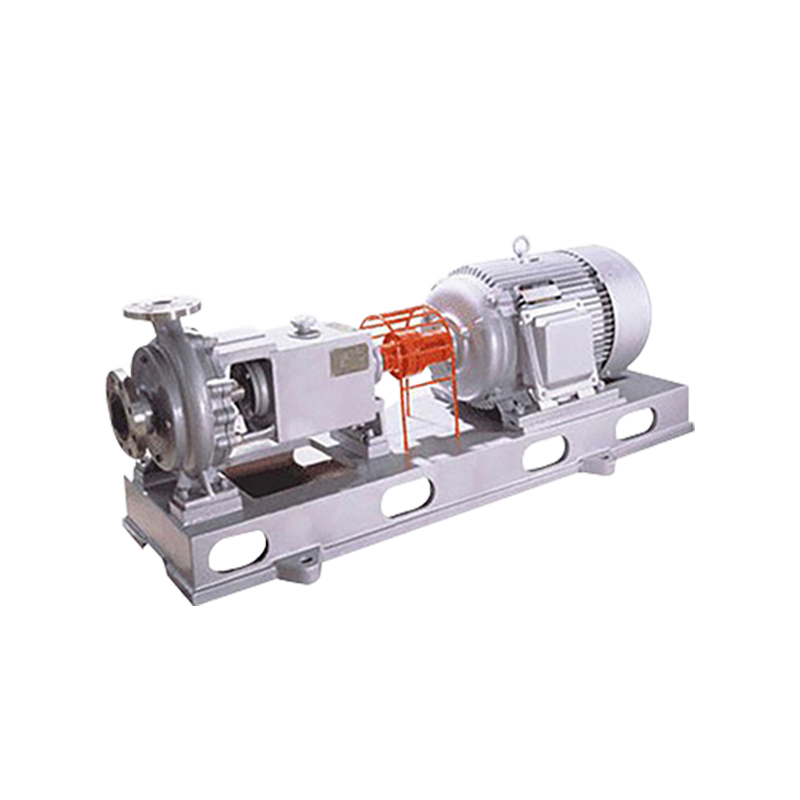

The chemical pump has a compact structure design, is easy to install, and occupies a small area, making it suitable for industrial environments with limited space. At the same time, the high-efficiency motor combined with the precision impeller design makes it run more smoothly, with lower noise, less vibration, and low maintenance workload.

4. Adapt to a variety of complex media

Whether it is high viscosity, strong volatility, particulate impurities or high-temperature liquid, the chemical pump can provide customized solutions. A variety of models such as self-priming chemical pumps, magnetic pumps, fluorine-lined pumps, metering pumps, etc. can be selected according to the characteristics of the medium to ensure efficient operation of the system.

Wide range of application industries

Chemical industry: used for the transportation and circulation of acid and alkali solutions and corrosive raw materials;

Pharmaceutical industry: used for the transportation of high-purity solutions and reactants;

Water treatment industry: adding chemicals and transporting waste liquids;

Electronics industry: semiconductor cleaning, etching liquid circulation;

Food industry: used for the transportation of liquids such as flavors, juices, and alcohol.

Our product advantages

As a professional chemical pump manufacturer, we adhere to the product concept of "safety, reliability and innovation". All chemical pump products are ISO certified and manufactured using international advanced technology. They have the following characteristics:

Long service life and worry-free continuous operation;

A variety of materials are available to meet the needs of different media;

Years of industry experience, providing customized solutions;

Perfect after-sales service, supporting global technical support and maintenance.

With the trend of increasing attention to environmental protection and safety in the chemical industry, choosing a high-quality, stable performance chemical pump is not only a guarantee of production safety, but also an important means for enterprises to reduce operation and maintenance costs and improve efficiency. If you are looking for a liquid delivery equipment that can withstand corrosive challenges, Chemical Pump will be your ideal choice.

en

en  русский

русский Español

Español